United States

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

(Mark One)

|

|

|

|

☑

|

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(D) OF THE SECURITIES EXCHANGE ACT OF 1934

FOR THE FISCAL YEAR ENDED December 31, 2015

|

|

|

|

|

☐

|

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(D) OF THE SECURITIES EXCHANGE ACT OF 1934

FOR THE TRANSITION PERIOD OF _________ TO _________.

|

Commission File Number: 001-33905

UR-ENERGY INC.

(Exact name of registrant as specified in its charter)

|

|

|

|

Canada

|

Not Applicable

|

|

State or other jurisdiction of incorporation or organization

|

(I.R.S. Employer Identification No.)

|

10758 West Centennial Road, Suite 200

Littleton, Colorado 80127

(Address of principal executive offices, including zip code)

Registrant’s telephone number, including area code: 720-981-4588

Securities registered pursuant to Section 12(b) of the Act:

|

|

|

|

Title of each class

|

Name of each exchange on which registered

|

|

Common Shares, no par value

|

NYSE MKT

|

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act

Yes ☐No ☑

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Exchange Act.

Yes ☐No ☑

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

Yes ☑No ☐

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files).

Yes ☑ No ☐

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ☐

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or smaller reporting company:

Large accelerated filer ☐ Accelerated filer ☑ Non-accelerated filer ☐ Smaller reporting company ☐

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act).

Yes ☐No ☑

As of February 25, 2016, there were 143,323,769 shares of the registrant’s no par value Common Shares (“Common Shares”), the registrant’s only outstanding class of voting securities, outstanding. As of June 30, 2015, the aggregate market value of the registrant’s voting Common Shares held by non-affiliates of the registrant was approximately $84.2 million based upon the closing sale price of the Common Shares as reported by the NYSE MKT. For the purpose of this calculation, the registrant has assumed that its affiliates as of June 30, 2015, included all directors and officers and two shareholders that held approximately 23.6 million of its outstanding Common Shares.

DOCUMENTS INCORPORATED BY REFERENCE

Certain information required for Items 10, 11, 12, 13 and 14 of Part III of this Annual Report on Form 10-K is incorporated by reference to the registrant’s definitive proxy statement for the 2016 Annual Meeting of Shareholders.

UR-ENERGY INC.

ANNUAL REPORT ON FORM 10-K

TABLE OF CONTENTS

When we use the terms “Ur-Energy,” “we,” “us,” “our,” or the “Company” we are referring to Ur-Energy Inc. and its subsidiaries, unless the context otherwise requires. We have included technical terms important to an understanding of our business under “Glossary of Common Terms” at the end of this section. Throughout this document we make statements that are classified as “forward-looking.” Please refer to the “Cautionary Statement Regarding Forward-Looking Statements” section of this document for an explanation of these types of assertions.

Cautionary Statement Regarding Forward-Looking Information

This annual report on Form 10-K contains "forward-looking statements" within the meaning of applicable United States and Canadian securities laws, and these forward-looking statements can be identified by the use of words such as "expect", "anticipate", "estimate", "believe", "may", "potential", "intends", "plans" and other similar expressions or statements that an action, event or result "may", "could" or "should" be taken, occur or be achieved, or the negative thereof or other similar statements. These statements are only predictions and involve known and unknown risks, uncertainties and other factors which may cause our actual results, performance or achievements, or industry results, to be materially different from any future results, performance, or achievements expressed or implied by these forward-looking statements. Such statements include, but are not limited to: (i) the ability to maintain steady state operations at Lost Creek and timing to ramp up to production rates at design capacity; (ii) the technical and economic viability of Lost Creek; (iii) the timing and outcome of permitting and regulatory approvals of the amendment for LC East and the KM horizon; (iv) the ability to complete additional favorable uranium sales agreements including spot sales if production is available and the market warrants; (v) the production rates and life of the Lost Creek Project and subsequent production from adjoining properties, including LC East; (vi) the potential of exploration targets throughout the Lost Creek Property (including the ability to expand resources); (vii) the potential of our other exploration and development projects, including Shirley Basin, as well as the technical and economic viability of Shirley Basin; (viii) the timing and outcome of applications for regulatory approval to build and operate an ISR mine at Shirley Basin; (ix) the outcome of our forecasts and production projections; and (x) the continuing and long-term effects on the uranium market of events in Japan in 2011 including supply and demand projections. These other factors include, among others, the following: future estimates for production, production ramp-up and operations (including any difficulties with continued ramp up), capital expenditures, operating costs, mineral resources, recovery rates, grades and market prices; business strategies and measures to implement such strategies; competitive strengths; estimates of goals for expansion and growth of the business and operations; plans and references to our future successes; our history of operating losses and uncertainty of future profitability; status as an exploration stage company; the lack of mineral reserves; risks associated with obtaining permits and other authorizations in the United States; risks associated with current variable economic conditions; our ability to service our debt and maintain compliance with all restrictive covenants related to the debt facilities and security documents; the possible impact of future financings; the hazards associated with mining production; compliance with environmental laws and regulations; uncertainty regarding the pricing and collection of accounts; the possibility for adverse results in potential litigation; uncertainties associated with changes in government policy and regulation; uncertainties associated with a Canada Revenue Agency or U.S. Internal Revenue Service audit of any of our cross border transactions; adverse changes in general business conditions in any of the countries in which we do business; changes in size and structure; the effectiveness of management and our strategic relationships; ability to attract and retain key personnel; uncertainties regarding the need for additional capital; uncertainty regarding the fluctuations of quarterly results; foreign currency exchange risks; ability to enforce civil liabilities under U.S. securities laws outside the United States; ability to maintain our listing on the NYSE MKT LLC (“NYSE MKT”) and Toronto Stock Exchange (“TSX”); risks associated with the expected classification as a "passive foreign investment company" under the applicable provisions of the U.S. Internal Revenue Code of 1986, as amended; risks associated with our investments and other risks and uncertainties described under the heading “Risk Factors” of this annual report.

Cautionary Note to U.S. Investors Concerning Disclosure of Mineral Resources

Unless otherwise indicated, all resource estimates included in this Form 10-K have been prepared in accordance with Canadian National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”) and the Canadian Institute of Mining, Metallurgy and Petroleum Definition Standards for Mineral Resources and Mineral Reserves (“CIM Definition Standards”). NI 43-101 is a rule developed by the Canadian Securities Administrators which establishes standards for all public disclosure an issuer makes of scientific and technical information concerning mineral projects. NI 43-101 permits the disclosure of an historical estimate made prior to the adoption of NI 43-101 that does not comply with NI 43-101 to be disclosed using the historical terminology if the disclosure: (a) identifies the source and date of the historical estimate; (b) comments on the relevance and reliability of the historical estimate; (c) to the extent known, provides the key assumptions, parameters and methods used to prepare the historical estimate; (d) states whether the historical estimate uses categories other than those prescribed by NI 43-101; and (e) includes any more recent estimates or data available.

Canadian standards, including NI 43-101, differ significantly from the requirements of the United States Securities and Exchange Commission (“SEC”), and resource information contained in this Form 10-K may not be comparable to similar information disclosed by U.S. companies. In particular, the term “resource” does not equate to the term “‘reserves”. Under SEC Industry Guide 7, mineralization may not be classified as a “reserve” unless the determination has been made that the mineralization could be economically and legally produced or extracted at the time the reserve determination is made. SEC Industry Guide 7 does not define and the SEC’s disclosure standards normally do not permit the inclusion of information concerning “measured mineral resources”, “indicated mineral resources” or “inferred mineral resources” or other descriptions of the amount of mineralization in mineral deposits that do not constitute “reserves” by U.S. standards in documents filed with the SEC. U.S. investors should also understand that “inferred mineral resources” have a great amount of uncertainty as to their existence and great uncertainty as to their economic and legal feasibility. It cannot be assumed that all or any part of an “inferred mineral resource” will ever be upgraded to a higher category. Under Canadian rules, estimated “inferred mineral resources” may not form the basis of feasibility or pre-feasibility studies except in rare cases. Investors are cautioned not to assume that all or any part of an “inferred mineral resource” exists or is economically or legally mineable. Disclosure of “contained ounces” in a resource is permitted disclosure under Canadian regulations; however, the SEC normally only permits issuers to report mineralization that does not constitute “reserves” by SEC standards as in-place tonnage and grade without reference to unit measures. Accordingly, information concerning mineral deposits set forth herein may not be comparable to information made public by companies that report in accordance with United States standards.

NI 43-101 Review of Technical Information: James A. Bonner, Ur-Energy Vice President Geology, P.Geo. and SME Registered Member, and Qualified Person as defined by National Instrument 43-101, reviewed and approved the technical information contained in this Annual Report.

Glossary of Common Terms and Abbreviations

|

|

|

|

Mineral Resource

|

is a concentration or occurrence of solid material of economic interest in or on the Earth’s crust in such form, grade or quality and quantity that there are reasonable prospects for eventual economic extraction. The location, quantity, grade or quality, continuity and other geological characteristics of a Mineral Resource are known, estimated or interpreted from specific geological evidence and knowledge, including sampling. CIM Definition Standards; NI 43-101, Section 1.1.

|

|

|

|

|

Inferred Mineral Resource

|

is that part of a Mineral Resource for which quantity and grade or quality are estimated on the basis of limited geological evidence and sampling. Geologic evidence is sufficient to imply but not verify geological and grade or quality continuity. An Inferred Mineral Resource has a lower level of confidence than that applying to an Indicated Mineral Resource and must not be converted to a Mineral Reserve. It is reasonably expected that the majority of Inferred Mineral Resources could be upgraded to Indicated Mineral Resources with continued exploration. CIM Definition Standards; NI 43-101, Section 1.1.

|

|

|

|

|

Indicated Mineral Resource

|

is that part of a Mineral Resource for which quantity, grade or quality, densities, shape and physical characteristics are estimated with sufficient confidence to allow the application of Modifying Factors in sufficient detail to support mine planning and evaluation of the economic viability of the deposit. Geological evidence is derived from adequately detailed and reliable exploration, sampling and testing and is sufficient to assume geological and grade or quality continuity between points of observation. An Indicated Mineral Resource has a lower level of confidence than that applying to a Measured Mineral Resource and may only be converted to a Probable Mineral Reserve. CIM Definition Standards; NI 43-101, Section 1.1.

|

|

|

|

|

Measured Mineral Resource

|

is that part of a Mineral Resource for which quantity, grade or quality, densities, shape, and physical characteristics are estimated with confidence sufficient to allow the application of Modifying Factors to support detailed mine planning and final evaluation of the economic viability of the deposit. Geological evidence is derived from detailed and reliable exploration, sampling and testing and is sufficient to confirm geological and grade or quality continuity between points of observation. A Measured Mineral Resource has a higher level of confidence than that applying to either an Indicated Mineral Resource or an Inferred Mineral Resource. It may be converted to a Proven Mineral Reserve or to a Probable Mineral Reserve. CIM Definition Standards; NI 43-101, Section 1.1.

|

|

|

|

|

Modifying Factors

|

are considerations used to convert Mineral Resources to Mineral Reserves. These include, but are not restricted to, mining, processing, metallurgical, infrastructure, economic, marketing, legal, environmental, social and governmental factors. CIM Definition Standards

|

|

|

|

|

Lithology

|

is a description of a rock; generally its physical nature. The description would address such things as grain size, texture, rounding, and even chemical composition. A lithologic description would be: coarse grained well rounded quartz sandstone with 10% pink feldspar and 1% muscovite.

|

|

|

|

|

PFN

|

is a modern geologic logging method known as Prompt Fission Neutron. PFN is considered a direct measurement of true uranium concentration (% U) and is used to verify the grades of mineral intercepts previously reported by gamma logging. PFN logging is accomplished by a down-hole probe in much the same manner as gamma logs, however only the mineralized interval plus a buffer interval above and below are logged.

|

Abbreviations:

|

|

|

|

BLM

|

U.S. Bureau of Land Management

|

|

CERCLA

|

Comprehensive Environmental Response and Liability Act

|

|

CIM

|

Canadian Institute of Mining, Metallurgy and Petroleum

|

|

DDW

|

Deep Disposal Well

|

|

eU3O8

|

equivalent U3O8 as measured by a calibrated gamma instrument

|

|

EMT

|

East Mineral Trend, located within our LC East Project (Great Divide Basin, Wyoming)

|

|

EPA

|

U.S. Environmental Protection Agency

|

|

GDB

|

Great Divide Basin, Wyoming

|

|

GPM

|

Gallons per minute

|

|

GT

|

Grade x Thickness product (% ft.) of a mineral intercept (expressed without units)

|

|

HH

|

Header house

|

|

IX

|

Ion Exchange

|

|

ISR

|

In Situ Recovery (literally, ‘in place’ recovery) (also known as in situ leach or ISL)

|

|

LT

|

Long-term (as relates to long-term pricing in the uranium market)

|

|

MMT

|

Main Mineral Trend, located within our Lost Creek Project (Great Divide Basin, Wyoming)

|

|

MU

|

Mine Unit (also referred to as wellfield)

|

|

NI 43-101

|

Canadian National Instrument 43-101 (Standards of Disclosure for Mineral Properties)

|

|

NRC

|

U.S. Nuclear Regulatory Commission

|

|

PEA

|

Preliminary Economic Assessment

|

|

PPM

|

Parts per million

|

|

RCRA

|

Resource Conservation and Recovery Act

|

|

SEC

|

U.S. Securities Exchange Commission

|

|

Unat

|

Uranium in its natural isotopic ratios

|

|

UIC

|

Underground Injection Control (pursuant to U.S. Environmental Protection Agency regulations)

|

|

U3O8

|

A standard chemical formula commonly used to express the natural form of uranium mineralization. U represents uranium and O represents oxygen.

|

|

USFWS

|

U.S. Fish and Wildlife Service

|

|

WDEQ

|

Wyoming Department of Environmental Quality (and its various divisions, LQD/Land Quality Division, WQD/Water Quality Division; AQD/Air Quality Division; and Solid and Hazardous Waste Division)

|

|

WEQC

|

Wyoming Environmental Quality Council

|

|

WGFD

|

Wyoming Game and Fish Department

|

Metric/Imperial Conversion Table

The imperial equivalents of the metric units of measurement used in this annual report are as follows:

|

|

|

|

|

|

Imperial Measure

|

Metric Unit

|

Metric Unit

|

Imperial Measure

|

|

2.4711 acres

|

1 hectare

|

0.4047 hectares

|

1 acre

|

|

2.2046 pounds

|

1 kilogram

|

0.4536 kilograms

|

1 pound

|

|

0.6214 miles

|

1 kilometer

|

1.6093 kilometers

|

1 mile

|

|

3.2808 feet

|

1 meter

|

0.3048 meters

|

1 foot

|

|

1.1023 short tons

|

1 tonne

|

0.9072 tonnes

|

1 short ton

|

Reporting Currency

All amounts in this report are expressed in United States dollars, unless otherwise indicated. The Financial Statements are presented in accordance with accounting principles generally accepted in the United States.

PART I

Items 1 and 2. BUSINESS AND PROPERTIES

Overview and Corporate Structure

Incorporated on March 22, 2004, Ur-Energy is an exploration stage mining company, as that term is defined in Securities and Exchange Commission (“SEC”) Industry Guide 7. We are engaged in uranium mining, recovery and processing activities, including the acquisition, exploration, development and operation of uranium mineral properties in the United States. We began operation of our first in situ recovery uranium mine at our Lost Creek Project, Wyoming in 2013. Ur-Energy is a corporation continued under the Canada Business Corporations Act on August 8, 2006. Our Common Shares are listed on the TSX under the symbol “URE” and on the NYSE MKT under the symbol “URG.”

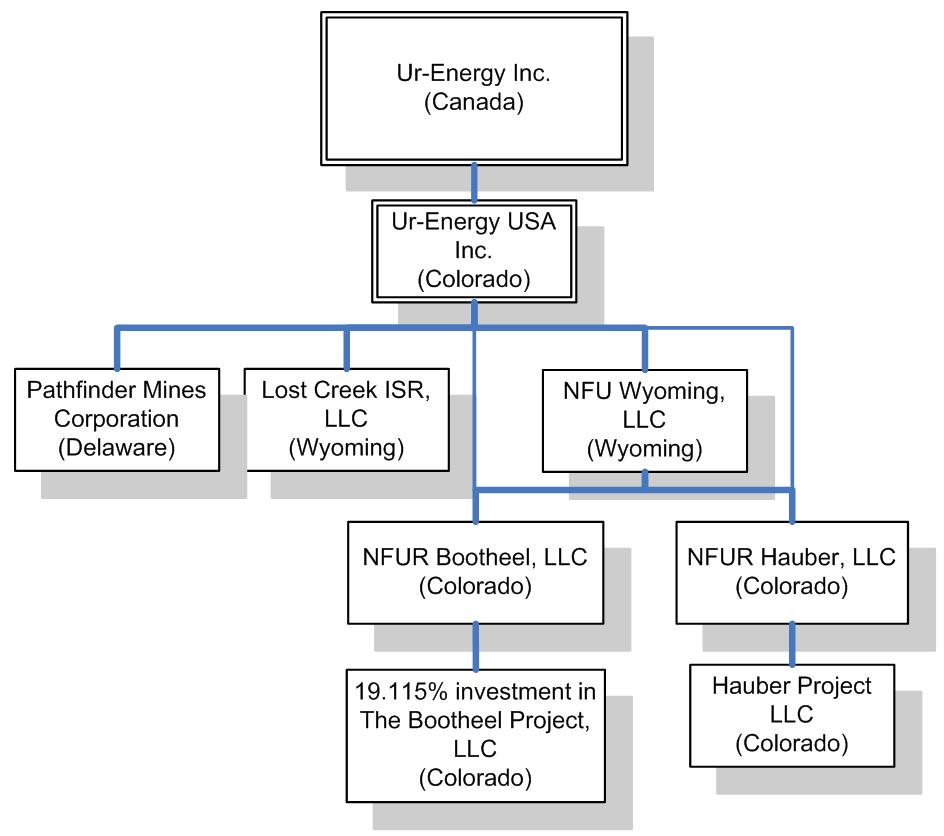

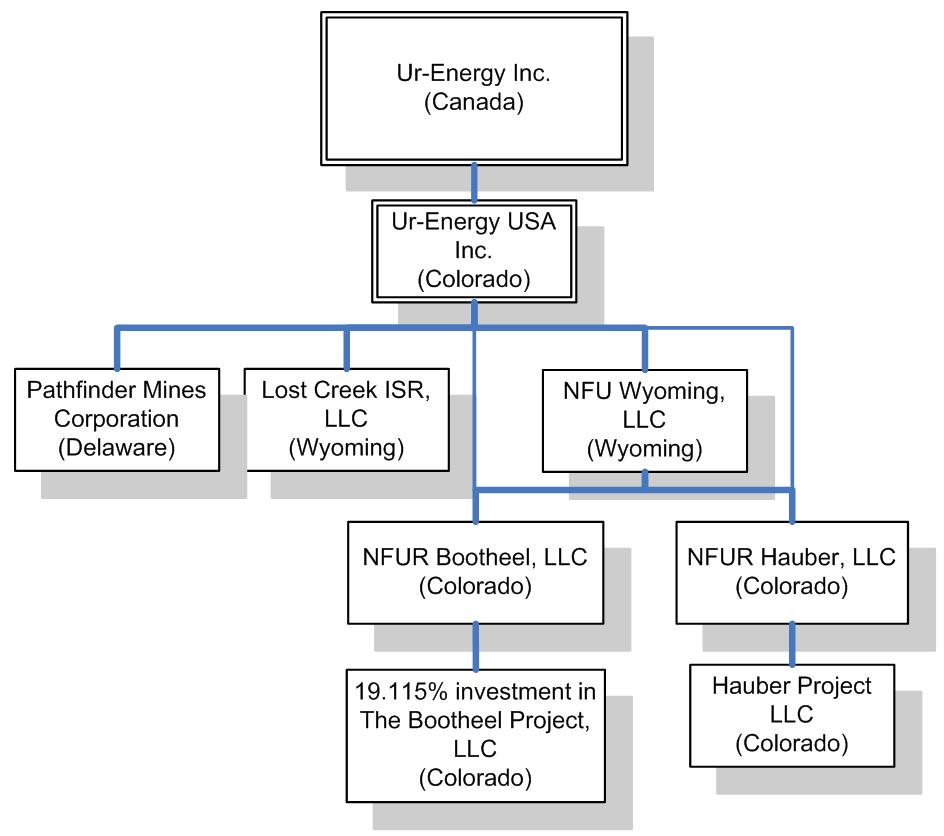

Ur-Energy has one direct wholly-owned subsidiary: Ur-Energy USA Inc. (“Ur-Energy USA”), a company incorporated under the laws of the State of Colorado.

Ur-Energy USA has three wholly-owned subsidiaries: NFU Wyoming, LLC (“NFU Wyoming”), a limited liability company formed under the laws of the State of Wyoming to facilitate acquisition of certain property and assets and, currently, to act as our land holding and exploration entity; Lost Creek ISR, LLC, a limited liability company formed under the laws of the State of Wyoming to hold and operate our Lost Creek Project and certain other of our Lost Creek properties and assets; and Pathfinder Mines Corporation (“Pathfinder”), a company incorporated under the laws of the State of Delaware, which holds, among other assets, the Shirley Basin and Lucky Mc properties in Wyoming.

Ur-Energy USA has two jointly held subsidiaries with NFU Wyoming: NFUR Bootheel, LLC (“NFUR Bootheel”), a limited liability company formed under the laws of the State of Colorado to facilitate participation in an exploration, mining and development agreement with Jet Metal Corp.; and NFUR Hauber, LLC (“NFUR Hauber”), a limited liability company formed under the laws of the State of Colorado to facilitate participation in a venture project at our Hauber project.

NFUR Hauber has one wholly-owned subsidiary: Hauber Project LLC, a limited liability company formed under the laws of the State of Colorado to hold our Hauber project. NFUR Hauber is the sole member and manager of Hauber Project LLC.

NFUR Bootheel holds an interest in The Bootheel Project, LLC, a limited liability company formed under the laws of the State of Colorado to hold the Bootheel property (and, formerly, the Buck Point property) is a venture with Jet Metal Corp., in which, at December 31, 2015, we own a 19.115% interest.

Currently, and at December 31, 2015, our principal direct and indirect subsidiaries, and affiliated entities, and the jurisdictions in which they were incorporated or organized, are as follows:

We are engaged in uranium mining, recovery and processing operations, in addition to the exploration and development of uranium mineral properties. Our wholly-owned Lost Creek Project in Sweetwater County, Wyoming is our flagship property. The project has been fully permitted and licensed since October 2012. We received operational approval from the U.S. Nuclear Regulatory Commission (“NRC”), and started production operation activities in August 2013. Our first sales of production from Lost Creek were made in December 2013; sales were made in every quarter of 2014 and 2015.

Currently, we have ten mid- and long-term uranium sales agreements in place with U.S. utilities for the sale of Lost Creek production or other yellowcake product at contracted pricing. Combined, these multi-year sales agreements represent a significant portion of our anticipated production into 2021. These agreements, individually, do not represent a substantial portion of our annual projected production, and our business is therefore not substantially dependent upon any one of the agreements.

The Company has contractually committed to sell 662,000 pounds of uranium yellowcake during 2016, at an average price of approximately US$47 per pound. During 2015, we worked with our customers to establish our delivery schedule for those commitments, with distribution of sales throughout the year. This schedule was created in an attempt to avoid uneven cash flows that could result from uneven delivery schedules. In mid-January 2016, certain deliveries with an anticipated schedule for first quarter delivery were moved to mid-year delivery dates, causing unevenness of cash flow in the first half of the year. This development was addressed promptly by the Company examining various alternatives in scheduling of deliveries and sales and other financing prospects.

Our newest project, Shirley Basin, is one of the assets we acquired as a part of the Pathfinder transaction which closed in December 2013. We also acquired all the historic geologic and engineering data for the project. During 2014, we completed a drill program of a limited number of confirmatory holes in order to complete an NI 43‑101 mineral resource estimate which was released in August 2014; subsequently, an NI 43-101 Preliminary Economic Assessment for Shirley Basin was completed in January 2015. Baseline studies necessary for the permitting and licensing of the project commenced in 2014 and were completed in 2015. Subsequently, in December 2015, our application for a permit to mine was submitted to the State of Wyoming Department of Environmental Quality (“WDEQ”). Work is well underway on other applications for necessary authorizations to mine at Shirley Basin.

We utilize in situ recovery of the uranium at Lost Creek and will do so at other projects where this is possible. The in situ recovery (ISR) technique is employed in uranium extraction because it allows for a lower cost and effective recovery of roll front mineralization. The in situ technique does not require the installation of tailings facilities or significant surface disturbance. This mining method utilizes injection wells to introduce a mining solution, called lixiviant, into the mineralized zone. The lixiviant is made of natural groundwater fortified with oxygen as an oxidizer, sodium bicarbonate as a complexing agent, and carbon dioxide for pH control. The complexing agent bonds with the uranium to form uranyl carbonate, which is highly soluble. The dissolved uranyl carbonate is then recovered through a series of production wells and piped to a processing plant where the uranyl carbonate is removed from the solution using Ion Exchange (IX) and captured on resin contained within the IX columns. The groundwater is re-fortified with the oxidizer and complexing agent and sent back to the wellfield to recover additional uranium. A low-volume bleed is permanently removed from the lixiviant flow. A reverse osmosis (RO) process is available to minimize the waste water stream generated. Brine from the RO process, if used, and bleed are disposed of by means of injection into deep disposal wells. Each wellfield is made up of dozens of injection and production wells installed in patterns to optimize the areal sweep of fluid through the uranium ore body.

Our Lost Creek processing facility includes all circuits for the capture, concentration, drying and packaging of uranium yellowcake for delivery into sales. Our processing facility, in addition to the IX circuit, includes dual processing trains with separate elution, precipitation, filter press and drying circuits (this is in contrast to certain other uranium in situ recovery facilities which operate as a capture plant (IX) only, and rely on agreements with other producers for the finishing, drying and packaging of their yellowcake end-product). Additionally, a restoration circuit including a RO unit was installed during initial construction to complete groundwater restoration once mining is complete.

The elution circuit (the first step after ion exchange) is utilized to transfer the uranium from the IX resin and concentrate it to the point where it is ready for the next phase of processing. The resulting rich eluate is an aqueous solution containing uranyl carbonate, salt and sodium carbonate and/or sodium bicarbonate. The precipitation circuit follows the elution circuit and removes the carbonate from the concentrated uranium solution and combines the uranium with peroxide to create a yellowcake crystal slurry. Filtration and washing is the next step, in which the slurry is loaded into a filter press where excess contaminants such as chloride are removed and a large portion of the water is removed. The final stage occurs when the dewatered slurry is moved

to a yellowcake dryer, which will further reduce the moisture content, yielding the final dried, free-flowing, product. Refined, salable yellowcake is packaged in 55-gallon steel drums.

The restoration circuit may be utilized in the production as well as the post-mining phases of the operation. The RO may initially be utilized to minimize the waste water stream generated during production. Once production is complete, the groundwater must be restored to its pre-mining class of use by removing a small portion of the groundwater and disposing of it (commonly known as sweep). Following sweep, the groundwater is treated utilizing RO and re-injecting the clean water. Finally, the groundwater is homogenized and sampled to insure the cleanup is complete, thus ending the mining process.

Our Lost Creek processing facility was constructed during 2012 – 2013, with production operations commencing in August 2013. Our first sales were made in December 2013. Nameplate design and NRC-licensed capacity of our Lost Creek processing plant is two million pounds per year, of which approximately one million pounds per year may be produced from our wellfields. The Lost Creek plant and the allocation of resources to mine units and resource areas were designed to generate approximately one million pounds of production per year at certain flow rates and uranium concentrations subject to regulatory and license conditions. Production of refined yellowcake was 727,246 pounds and 547,992 pounds in 2015 and 2014, respectively. The excess capacity in the design of the processing circuits of the plant is intended, first, to facilitate routine (and, non-routine) maintenance on any particular circuit without hindering production operational schedules. The capacity was also designed to permit us to process uranium from other of our mineral projects in proximity to Lost Creek if circumstances warrant in the future (e.g., Shirley Basin Project), or, alternatively to be able to contract to toll mill/process product from other in situ uranium mine sites in the region. This design would permit us to conduct either of these activities while Lost Creek is producing and processing uranium and/or in years following Lost Creek production from wellfields during final restoration activities.

Our Lost Creek processing facility includes all circuits for the production, drying and packaging of uranium yellowcake for delivery into sales. As contemplated in the Preliminary Economic Assessment of Shirley Basin, we expect that the Lost Creek processing facility may be utilized for the drying and packaging of uranium from Shirley Basin, for which we currently anticipate the need only for a satellite plant. However, the Shirley Basin permit application contemplates the construction of a full processing facility, providing greater construction and operating flexibility as may be dictated by market conditions.

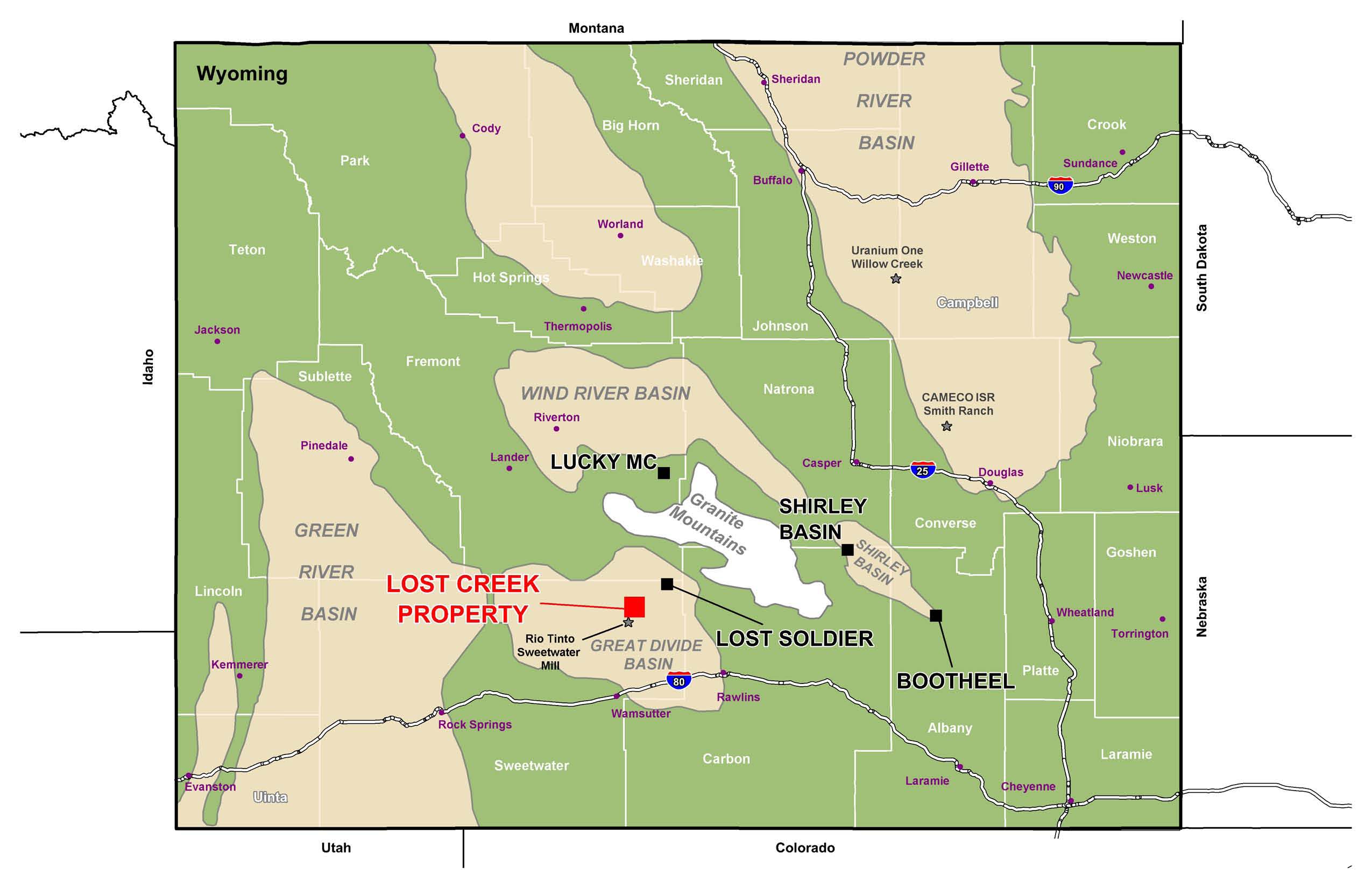

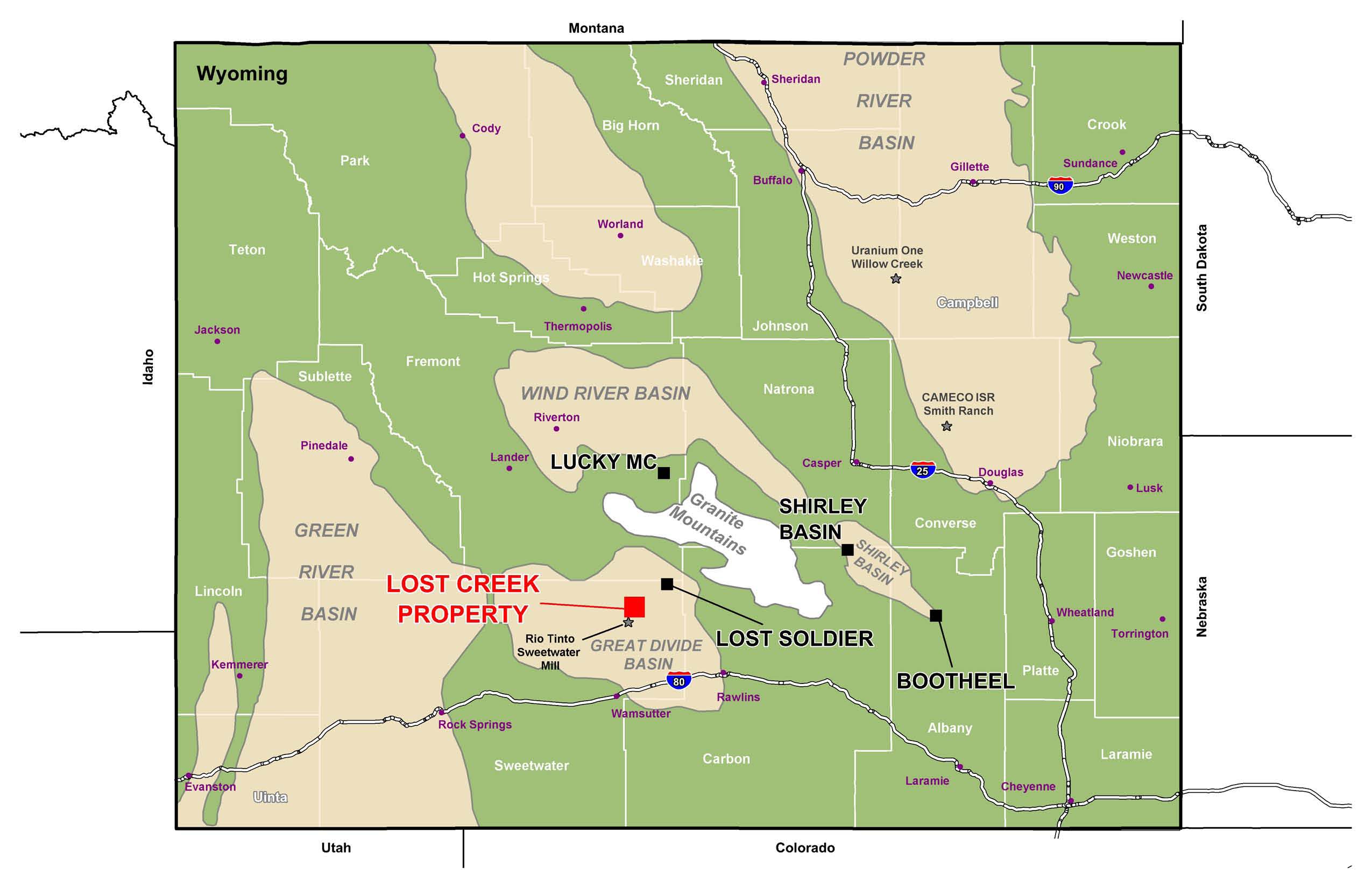

Our Mineral Properties

Our current land portfolio includes 14 projects in Wyoming. Ten of these projects are in the Great Divide Basin, Wyoming, including our flagship project, Lost Creek Project, which began production operations in August 2013. Currently we control a total of more than 2,100 unpatented mining claims and four State of Wyoming mineral leases for a total of more than 42,000 acres (16,997 hectares) in the area of the Lost Creek Property, including the Lost Creek permit area (the “Lost Creek Project” or “Lost Creek”) and certain adjoining properties which we refer to as LC East, LC West, LC North, LC South and EN project areas (collectively, with the Lost Creek Project, the “Lost Creek Property”). Five of the projects at the Lost Creek Property contain NI 43-101 compliant mineral resources: Lost Creek, LC East, LC West, LC South and LC North. See Resource Summary

below in Technical Developments. Below is a map showing our Wyoming projects and the geologic basins in which they are located.

Our Wyoming properties together total more than 66,000 acres (approximately 27,000 hectares) and include two properties, Shirley Basin and Lucky Mc, obtained through our acquisition of Pathfinder Mines Corporation in December 2013.

Operating Properties

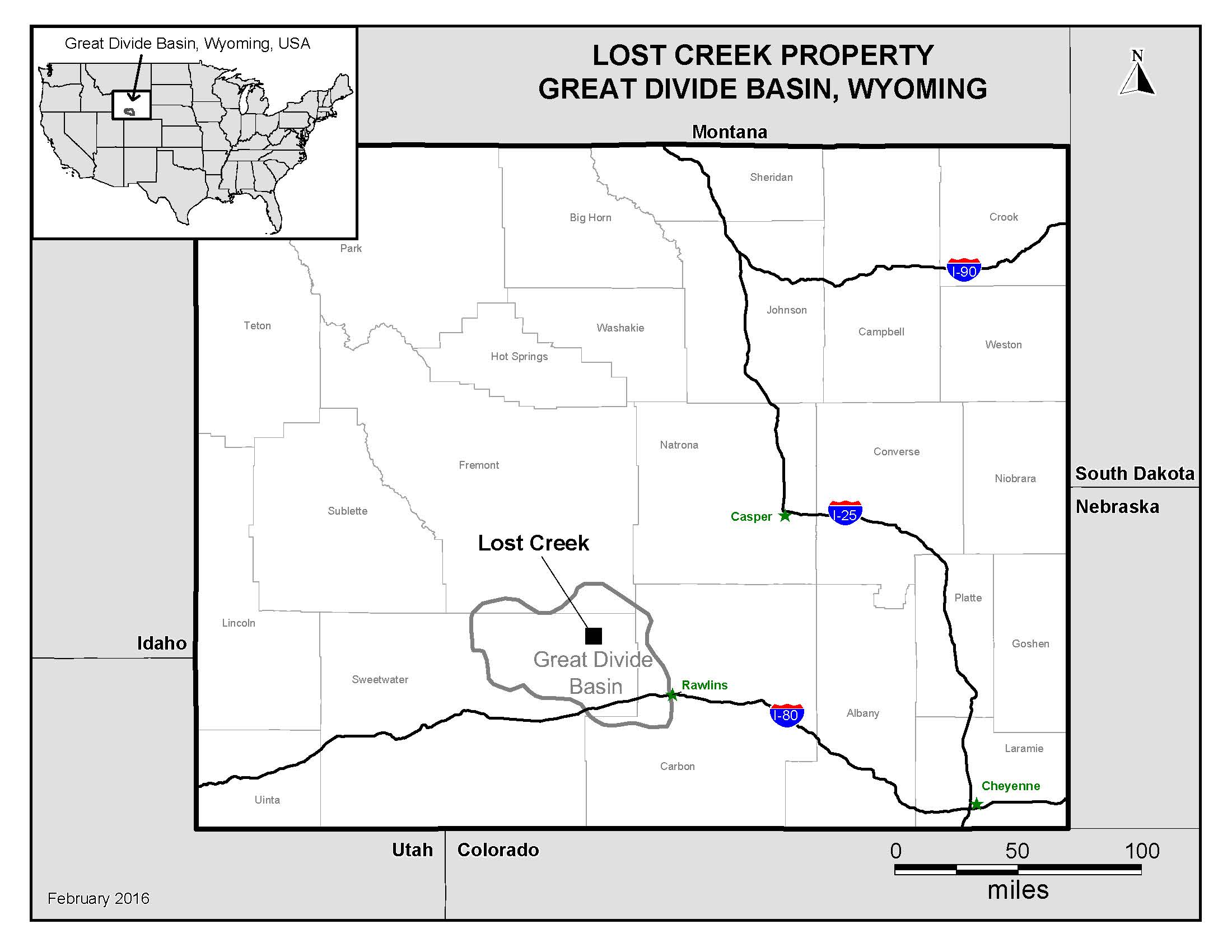

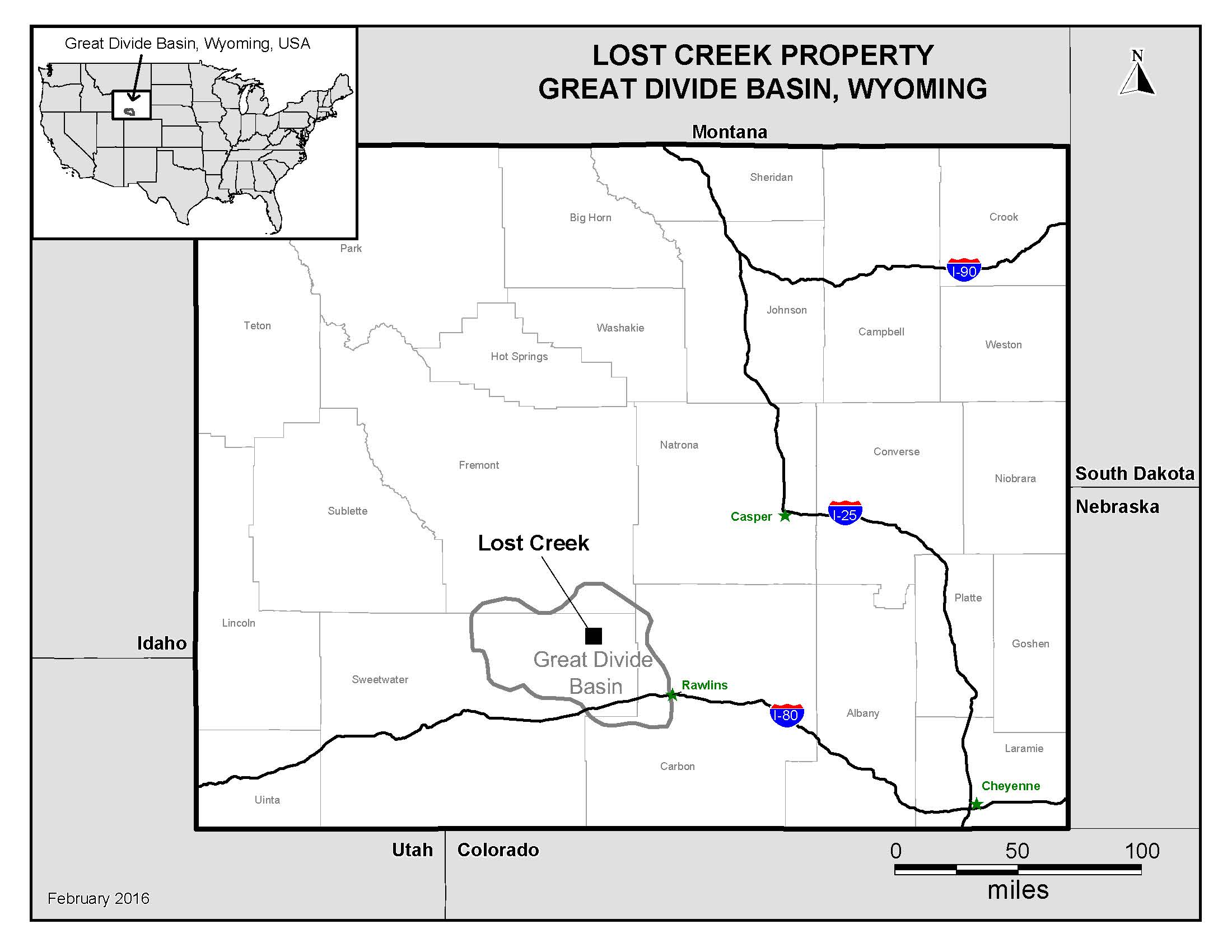

Lost Creek Project – Great Divide Basin, Wyoming

The Lost Creek Project area was acquired in 2005, and is located in the Great Divide Basin, Wyoming. The Main Mineral Trend of the Lost Creek uranium deposit (the “MMT”) is located within the Lost Creek Project. The permit area of the Lost Creek Project covers 4,254 acres (1,722 hectares), comprising 201 lode mining claims and one State of Wyoming mineral lease section. Regional access relies almost exclusively on existing public roads and highways. The local and regional transportation network consists of primary, secondary, local and unimproved roads. Direct access to Lost Creek is mainly on two crown-and-ditched gravel paved access roads to the processing plant. One road enters from the west off of Sweetwater County Road 23N (Wamsutter-Crooks Gap Road); the other enters from the east off of U.S. Bureau of Land Management (“BLM”) Sooner Road. On a wider basis, from population centers, the Property area is served by an Interstate Highway (Interstate 80), a US Highway (US 287), Wyoming state routes (SR 220 and 73 to Bairoil), local county roads, and BLM roads. The Lost Creek Property is located as shown here:

The basic infrastructure (power, water, and transportation) necessary to support our ISR operation is located within reasonable proximity. Generally, the proximity of Lost Creek to paved roads is beneficial with respect to transportation of equipment, supplies, personnel and product to and from the property. Existing regional

overhead electrical service is aligned in a north-to-south direction along the western boundary of the Lost Creek Project. A new overhead power line, approximately two miles in length, was constructed to bring power from the existing Pacific Power line to the Lost Creek plant. Power drops have been made to the property and distributed to the plant, offices, wellfields, and other facilities.

Following the purchase of an existing production royalty with respect to 20 claims of the Lost Creek Project in 2013, there are no remaining royalties at the Lost Creek Project, except for the royalty on the State of Wyoming section mineral lease as provided by law. Currently, there is only limited production planned from the State lease section. There is a production royalty of one percent on certain claims of the LC East Project, and other royalties on other claims within the other adjoining projects (LC South and EN projects) as well as the other State sections on which we maintain mineral leases (LC West and EN projects).

Production Operations

Following receipt of the final regulatory authorization in October 2012, we commenced construction at Lost Creek. Construction included the plant facility and office building, installation of all process equipment, installation of two access roads, additional power lines and drop lines, deep disposal wells, construction of two holding ponds, warehouse building, and drill shed building. In August 2013 we were given operational approval by the NRC and commenced production operation activities. See also discussion of the operational methods used at Lost Creek, above, under heading “Business and Properties.”

For the Lost Creek PEA, in order to accurately reflect existing resources, all resources produced through September 30, 2015 (1,358,407 pounds) were subtracted from total Measured Resources from the HJ Horizon in MU1. All the wells to support the originally-planned 13 header houses (“HHs”) have been completed. Surface installations for HHs 1-1 through 1-12 have been installed and HHs 1-1 through 1-11 were operational as of October 15, 2015. Header house 12 was brought online in November. Construction of header house 13 is underway.

All monitor ring wells have been installed and pump-tested in MU2. As of October 15, 2015, the effective date for the Lost Creek PEA, 138 pattern wells have been piloted within HHs 2-1, 2-2 and 2-3 (at December 31, 2015, 179 pattern wells were piloted). Additionally, two applications for amendments to the license and permits have been submitted. The two applications seek to authorize production in the KM Horizon within the Lost Creek Project and to authorize production in the HJ and KM Horizons within the EMT in the LC East Project.

During 2015, 783,547 pounds of U3O8 were captured within the Lost Creek plant; 727,245 pounds U3O8 were packaged in drums; and 717,125 pounds U3O8 of drummed inventory were shipped from the Lost Creek processing plant to the converter. At December 31, inventory at the conversion facility was approximately 63,776 pounds U3O8.

From production, Lost Creek sold 725,000 pounds U3O8 during calendar 2015 at an average price of US$41.33 per pound. Total sales for 2015, including purchased U3O8, was 925,000 pounds at an average price of US$45.20 per pound. Contract sales were as expected (630,000 pounds at an average price of US$49.42 per pound); however, spot sales were lower than expected (295,000 pounds at an average price of US$36.18) due to the continuing low spot price environment.

After more than two years of operations, the 2015 average plant head grade remained at 97 ppm despite having somewhat lower head grades for the fourth quarter. Head grade during December was 87 ppm, which was above the quarter’s average grade of 85 ppm. The lower head grade during this period of operation, as well as varying month-to-month grades, is a typical result as the mine matures and older operating patterns remain in the flow regime while newer patterns are brought online. This maturation of mine is also demonstrated through the increasing average flowrates, with a 454 gpm (23.5%) increase quarter-over-quarter.

Updated Preliminary Economic Assessment for Lost Creek Property

In January 2016, we issued an updated Preliminary Economic Assessment for the Lost Creek Property Sweetwater County Wyoming (January 19, 2016 (TREC, Inc.)), which was then amended February 8, 2016 to include two additional tables to supplement the Cash Flow and OPEX tables as set forth in the prior document (as amended, the “Lost Creek PEA”). The Lost Creek PEA was prepared for the Company and its subsidiary, Lost Creek ISR, LLC, by Douglass H. Graves, P.E., TREC, Inc. (“TREC”) and James A. Bonner, C.P.G., Vice President Geology of the Company in accordance with NI 43-101.

According to the Lost Creek PEA, the current mineral resources at the Lost Creek Property are as follows:

Lost Creek Property - Resource Summary

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MEASURED

|

|

INDICATED

|

|

INFERRED

|

|

PROJECT

|

AVG GRADE

|

SHORT TONS

|

POUNDS

|

|

AVG GRADE

|

SHORT TONS

|

POUNDS

|

|

AVG GRADE

|

SHORT TONS

|

POUNDS

|

|

|

% eU3O8

|

(X 1000)

|

(X 1000)

|

|

% eU3O8

|

(X 1000)

|

(X 1000)

|

|

% eU3O8

|

(X 1000)

|

(X 1000)

|

|

LOST CREEK

|

0.048

|

8,339

|

7,937

|

|

0.046

|

3,831

|

3,491

|

|

0.046

|

3,116

|

2,844

|

|

MU1 production through 9/30/15

|

(0.048)

|

(1,415)

|

(1,358)

|

|

|

|

|

|

|

|

|

|

LC EAST

|

0.052

|

1,392

|

1,449

|

|

0.041

|

1,891

|

1,567

|

|

0.042

|

2,954

|

2,484

|

|

LC NORTH

|

-----

|

-----

|

-----

|

|

-----

|

-----

|

-----

|

|

0.045

|

645

|

581

|

|

LC SOUTH

|

-----

|

-----

|

-----

|

|

0.037

|

220

|

165

|

|

0.039

|

637

|

496

|

|

LC WEST

|

-----

|

-----

|

-----

|

|

-----

|

-----

|

-----

|

|

0.109

|

16

|

34

|

|

EN

|

-----

|

-----

|

-----

|

|

-----

|

-----

|

-----

|

|

-----

|

-----

|

-----

|

|

GRAND TOTAL

|

0.048

|

8,316

|

8,028

|

|

0.044

|

5,942

|

5,223

|

|

0.044

|

7,368

|

6,439

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MEASURED + INDICATED =

|

14,258

|

13,251

|

|

|

|

|

Notes:

|

1.

| |

Sum of Measured and Indicated tons and pounds may not add to the reported total due to rounding. |

|

2.

| |

% eU3O8 is a measure of gamma intensity from a decay product of uranium and is not a direct measurement of uranium. Numerous comparisons of eU3O8 and chemical assays of Lost Creek rock samples, as well as PFN logging, indicate that eU3O8 is a reasonable indicator of the chemical concentration of uranium. |

|

3.

| |

Table shows resources based on grade cutoff of 0.02 % eU3O8 and a grade x thickness cutoff of 0.20 GT. |

|

4.

| |

Measured, Indicated, and Inferred Mineral Resources as defined in Section 1.2 of NI 43-101 (the CIM Definition Standards (CIM Council, 2014)). |

|

5.

| |

Resources are reported through October 15, 2015. |

|

6.

| |

All reported resources occur below the static water table. |

|

7.

| |

1,358,407 lbs. of uranium have been produced from the HJ Horizon in MU1 (Lost Creek Project) as of September 30, 2015. |

|

8.

| |

Mineral resources that are not mineral reserves do not have demonstrated economic viability. |

Information shown in the table above differs from the disclosure requirements of the SEC. See Cautionary Note to U.S. Investors Concerning Disclosure of Mineral Resources, above.

The Lost Creek PEA discloses changes for the Lost Creek Property which come in the form of an updated mineral resource estimate prompted by recent drilling within Lost Creek’s Mine Unit 2 (“MU2”), exploratory drilling at the Lost Creek and LC East Projects, and the re-estimation of all previously-identified resources for the Property at a revised 0.20 grade-thickness (GT) cut-off. The economic analyses within the Lost Creek PEA have been revised to evaluate the impact of additional identified resources with information and data acquired through two years of ISR operations at Lost Creek. The Lost Creek PEA therefore serves to replace the last

economic analyses for the Lost Creek Property from December 2013 and the most recent NI 43-101 Technical Report on the Lost Creek Property, dated June 17, 2015. The Lost Creek PEA covers production through September 30, 2015 and drilling and other exploration and operational activities conducted through October 15, 2015.

On June 17, 2015, the Company published an independent Technical Report for the Lost Creek Property to report increased resources for its operating Mine Unit 1 (“MU1”) and from exploration drilling conducted early in 2015. In order to reconcile higher-than-expected uranium recoveries from production operations in this mine unit, the grade thickness (“GT”) cutoff for uranium intercepts used in resource estimation was lowered from 0.30 to 0.20. Employing these revised guidelines, resources for MU1 were re-mapped and re-evaluated, increasing the MU1 Measured Resources by 55% (after subtraction of MU1 production). Through the monitoring of continued production from MU1, the authors believe the 0.20 GT better represents the in-situ uranium resources for the Lost Creek Property. Accordingly, for the Lost Creek PEA, all resource estimations for Lost Creek Property have used the new 0.20 GT cutoff, again, following re-mapping and re-evaluation. Since the June 17, 2015 Technical Report, our activities have resulted in a cumulative increase of mineral resources at the Lost Creek Property of 31% in the Measured and Indicated categories and 28% in the Inferred category.

The Lost Creek Property represents the composite of six individual contiguous Projects: Lost Creek Project, LC East Project, LC West Project, LC North Project, LC South Project and EN Project. The fully-licensed and operating Lost Creek Project is considered the core project while the others are collectively referred to as the Adjoining Projects. The Adjoining Projects were acquired by the Company as exploration targets to provide resources supplemental to those recognized at the Lost Creek Project. Most were initially viewed as stand-alone projects, but expanded over time such that collectively they represent a contiguous block of land along with the Lost Creek Project.

The Lost Creek PEA mineral resource estimate includes drill data and analyses of approximately three thousand two hundred historic and current holes and over 1.8 million feet of drilling at the Lost Creek Project alone. With the acquisition of Lost Creek project, we acquired logs and analyses from 569 historic holes representing 366,268 feet of data. Since our acquisition of the project we have drilled 2,629 holes and wells including the construction and development drilling during 2013-2015 for Mine Unit 1 and initial work in Mine Unit 2 at Lost Creek. Drilling at Lost Creek through October 15, 2015 was included in the PEA. Additionally, drilling from the other five projects at the Lost Creek Property, both historic and our drill programs, is included in the mineral resource estimate. Collectively, this represents an additional 2,387 drillholes (1,306,331 feet).

Regulatory Authorizations and Land Title of Lost Creek

Beginning in 2007, we completed all necessary applications and related processes to obtain the required permitting and licenses for the Lost Creek Project, of which the three most significant are: a Source and Byproduct Materials License from the NRC (received August 2011); a Plan of Operations with the BLM (Record of Decision (“ROD”) received October 2012; affirmed by U.S. District Court for the District of Wyoming, September 2013); and a Permit and License to Mine from the WDEQ (October 2011). The WDEQ License to Mine was issued following determinations in favor of the project by the WEQC with respect to a third-party objection, which included a WEQC direction that the WDEQ Permit be approved by the WDEQ. The WDEQ Permit includes the approval of the first mine unit, as well as the Wildlife Management Plan, including a positive determination of the protective measures at the project for the greater sage-grouse species.

In March 2010, the USFWS submitted a finding of “warranted for listing but precluded by higher priorities” with regard to the greater sage-grouse, whose habitat includes Wyoming. A finding that listing is “warranted but precluded” results in recognition of the greater sage-grouse as a candidate for listing as a threatened or endangered species. Pursuant to a settlement agreement, issued as a consent decree of a federal district court,

the USFWS was required to make a listing decision on or before September 30, 2015. In compliance with the consent decree, the USFWS issued a decision that the species did not warrant listing.

Potential risks to the accessibility of the estimated mineral resource may include changes in the designation of the sage grouse as an endangered species by the USFWS because the Lost Creek Property lies within a sage grouse core area as defined by the state of Wyoming. In September 2015, the USFWS issued its finding that the greater sage grouse does not warrant protection under the Endangered Species Act (ESA). The USFWS reached this determination after evaluating the species’ population status, along with the collective efforts by the BLM and U.S. Forest Service, state agencies, private landowners and other partners to conserve its habitat.

After a thorough analysis of the best available scientific information and taking into account ongoing key conservation efforts and their projected benefits, the USFWS determined the species does not face the risk of extinction now or in the foreseeable future and therefore does not need protection under the ESA. Should future decisions vary, or state or federal agencies alter their management of the species, there could potentially be an impact on future expansion operations. However, the Company continues to work closely with the Wyoming Game and Fish Department (“WGFD”) and the BLM to mitigate impacts to the sage grouse.

As a part of the Lost Creek WDEQ Application, we submitted a Wildlife Protection Plan addressing, among other issues, the sage-grouse. The WGFD reviewed and recommended the Wildlife Management Plan to the WDEQ, including findings that the Wildlife Management Plan meets all of the protection measures for the greater sage-grouse species, and is consistent with the Wyoming Governor’s Executive Order on the sage-grouse. Following WGFD’s recommendation, the Lost Creek Wildlife Management Plan was incorporated into the WDEQ Permit, and subsequently upheld by the WEQC rulings.

The State of Wyoming has developed a “core-area strategy” to help protect the greater sage-grouse species within certain core areas of the state. Exploration areas of our Lost Creek property are all within a designated core area and are thus subject to work activity restrictions from March 1 to July 15 of each year. The timing restriction precludes exploration drilling and other non-operational based activities which may disturb the sage-grouse. The sage-grouse timing restrictions relevant to ISR production and operational activities at the Lost Creek Project are somewhat different because the State has recognized that mining projects within core areas must be allowed to operate year-round. Therefore, there are no timing restrictions on drilling, construction, or operational activities within pre-approved disturbed areas within our permit to mine.

Meanwhile, in related regulatory processes, the BLM prepared environmental impact statements for and issued amendments to eleven Resource Management Plans (“RMPs”), related to the greater sage-grouse. Included in these RMPs are proposals to designate millions of acres of federal lands currently open for mineral location as lands to be withdrawn from such mineral status.

Additional authorizations from federal, state and local agencies for the Lost Creek project include: WDEQ-Air Quality Division Air Quality Permit and WDEQ-Water Quality Division Class I Underground Injection Control (“UIC”) Permit. The latter permit allows Lost Creek to operate up to five Class I injection wells to meet the anticipated disposal requirements for the life of the Lost Creek Project. The Environmental Protection Agency (“EPA”) issued an aquifer exemption for the Lost Creek project. The WDEQ’s separate approval of the aquifer reclassification is a part of the WDEQ Permit. We also received approval from the EPA and the Wyoming State Engineer’s Office for the construction and operation of two holding ponds at Lost Creek.

In 2014, two applications for amendments to the primary authorizations to mine at Lost Creek were submitted to federal regulatory agencies, NRC and BLM, for the development and mining of LC East Project and the KM Horizon at Lost Creek. In 2015, the BLM issued a notice of intent to complete an environmental impact statement for the application. The NRC will participate in this review as a cooperating agency. A permit

amendment requesting approval to mine at the LC East Project and within the KM Horizon at the Lost Creek Project was also submitted to the WDEQ for review and approval. Approval will include an aquifer exemption. The air quality permit will be revised to account for additional surface disturbance. An application will be submitted to Sweetwater County to re-zone the land at LC East. A subsequent Development Plan will also have to be submitted for review and approval. Numerous well permits from the State Engineer’s Office will be required.

A WDEQ draft permit for Underground Injection Control (UIC) Class V wells has been completed for Lost Creek. It is anticipated that final approvals from all regulators will be received in first quarter 2016. These approvals will allow for the onsite disposal of fresh permeate (i.e., clean water) into relatively shallow Class V wells. Site operators will use the reverse osmosis circuits, which were installed during initial construction of the plant, to treat process waste water into brine and permeate streams. The brine stream will continue to be disposed of in the UIC Class I deep wells while the clean, permeate stream will be injected into the UIC Class V wells. It is expected that these operational procedures, which are expected to be commissioned and fully operational in second quarter 2016, will significantly enhance waste water disposal capacity at the site.

Through certain of our subsidiaries, we control the federal unpatented lode mining claims and State of Wyoming mineral leases which make up the Lost Creek Property. Title to the mining claims is subject to rights of pedis possessio against all third-party claimants as long as the claims are maintained. The mining claims do not have an expiration date. Affidavits have been timely filed with the BLM and recorded with the Sweetwater County Recorder attesting to the payment of annual maintenance fees to the BLM as established by law from time to time. The state leases have a ten-year term, subject to renewal for successive ten-year terms.

The surface of all the mining claims is controlled by the BLM, while we have the right to use as much of the surface as is necessary for exploration and mining of the claims, subject to compliance with all federal, state and local laws and regulations. Surface use on BLM lands is administered under federal regulations. Similarly, access to state-controlled land is largely inherent within the State of Wyoming mineral lease. The state lease at the Lost Creek Project requires a nominal surface impact fee to be paid. The other state mineral leases currently do not have surface impact payment obligations.

Exploration and Development Properties

Our Five Projects Adjoining Lost Creek Together with the Lost Creek Project Form the Lost Creek Property

The LC East and LC West Projects (currently, approximately 5,710 acres (2,130 hectares) and 3,840 acres (1,554 hectares), respectively) were added to the Lost Creek Property in 2012. The two projects were formed through location of new unpatented lode mining claims and an asset exchange completed in February 2012 with Uranium One Americas, Inc., through which we acquired 175 unpatented mining claims and related data. In 2012, all baseline studies at LC East were initiated. As discussed above, in 2014, we submitted applications for amendments of the Lost Creek licenses and permits to include development of LC East. We also located additional lode mining claims to secure the lands in what will be the LC East permit area. The East Mineral Trend (the “EMT”) is a second mineral trend of significance, in addition to the MMT at Lost Creek, identified by historic drilling on the lands forming LC East. Although geologically similar, it appears to be a separate and independent trend from the MMT. The Lost Creek PEA contains a recommendation that delineation drilling of identified resources in the EMT continue, together with progressing all necessary permit and license amendment to permit future production.

The LC North Project (approximately 7,730 acres (3,120 hectares)) is located to the north and to the west of the Lost Creek Project. Historical wide-spaced exploration drilling on this project consisted of 175 drill holes. The

Company has conducted two drilling programs at the project. Exploration drilling at LC North is recommended by Company staff to pursue the potential of an extension of the MMT in the HJ and KM horizons.

The LC South Project (approximately 10,775 acres (4,360 hectares)) is located to the south and southeast of the Lost Creek Project. Historical drilling on the LC South Project consisted of 488 drill holes. In 2010, the Company drilled 159 exploration holes (total, 101,270 feet (30,867 meters)) which confirmed numerous individual roll front systems occurring within several stratigraphic horizons correlative to mineralized horizons in the Lost Creek Project. Also, a series of wide-spaced drill holes were part of this exploration program which identified deep oxidation (alteration) that represents the potential for several additional roll front horizons. Staff also recommend that the HJ and KM horizons should be further explored, and suggest that additional drilling be conducted to further evaluate the potential of deeper mineralization.

The EN Project (approximately 10,122 acres (4,096 hectares)) is adjacent to and east of LC South. Ur-Energy has over 50 historical drill logs from the EN project. Some minimal, deep, exploration drilling has been conducted at the project. Although no mineral resource is yet reported due to the limited nature of the data, Company geologists continue to recommend that the EN project should be explored further with wide spaced framework drilling to assess regional alteration and stratigraphic relationships.

History and Geology of the Lost Creek Property

Uranium was discovered in the Great Divide Basin, where Lost Creek is located, in 1936. Exploration activity increased in the early 1950s after the Gas Hills District discoveries, and continued to increase in the 1960s, with the discovery of numerous additional occurrences of uranium. Wolf Land and Exploration (which later became Inexco), Climax (Amax) and Conoco Minerals were the earliest operators in the Lost Creek area and made the initial discoveries of low-grade uranium mineralization in 1968. Kerr-McGee, Humble Oil, and Valley Development, Inc. were also active in the area. Drilling within the current Lost Creek Project area from 1966 to 1976 consisted of approximately 115 wide-spaced exploration holes by several companies including Conoco, Climax (Amax), and Inexco.

Texasgulf acquired the western half of what is now the Lost Creek Project in 1976 through a joint venture with Climax and identified what is now referred to as the Main Mineral Trend (MMT). In 1978, Texasgulf optioned into a 50% interest in the adjoining Conoco ground to the east and continued drilling, fully identifying the MMT eastward to the current Project boundary; Texasgulf drilled approximately 412 exploration holes within what is now the Lost Creek Project. During this period Minerals Exploration Company (a subsidiary of Union Oil Company of California) drilled approximately 8 exploration holes in what is currently the western portion of the Lost Creek Project. Texasgulf dropped the project in 1983 due to declining market conditions. The ground was subsequently picked up by Cherokee Exploration, Inc. which conducted no field activities.

In 1987, Power Nuclear Corporation (also known as PNC Exploration) acquired 100% interest in the project from Cherokee Exploration, Inc. PNC Exploration conducted a limited exploration program and geologic investigation, as well as an evaluation of previous in situ leach testing by Texasgulf. PNC Exploration drilled a total of 36 holes within the current Project area.

In 2000, New Frontiers Uranium, LLC acquired the property and database from PNC Exploration, but conducted no drilling or geologic studies. New Frontiers Uranium, LLC later transferred the Lost Creek Project-area property along with its other Wyoming properties to its successor NFU Wyoming, LLC. In June 2005, Ur-Energy USA purchased 100% ownership of NFU Wyoming, LLC.

The Lost Creek Property is situated in the northeastern part of the GDB which is underlain by up to 25,000 ft. of Paleozoic to Quaternary sediments. The GDB lies within a unique divergence of the Continental Divide and is bounded by structural uplifts or fault displaced Precambrian rocks, resulting in internal drainage and an independent hydrogeologic system. The surficial geology in the GDB is dominated by the Battle Spring Formation of Eocene age. The dominant lithology in the Battle Spring Formation is coarse arkosic sandstone, interbedded with intermittent mudstone, claystone and siltstone. Deposition occurred as alluvial-fluvial fan deposits within a south-southwest flowing paleodrainage. The sedimentary source is considered to be the Granite Mountains, approximately 30 miles to the north. Maximum thickness of the Battle Spring Formation sediments within the GDB is 6,000 ft.

Uranium deposits in the GDB are found principally in the Battle Spring Formation, which hosts the Lost Creek Project deposit. Lithology within the Lost Creek deposit consists of approximately 60% to 80% poorly consolidated, medium to coarse arkosic sands up to 50 ft. thick, and 20% to 40% interbedded mudstone, siltstone, claystone and fine sandstone, each generally less than 25 ft. thick. This lithological assemblage remains consistent throughout the entire vertical section of interest in the Battle Spring Formation.

Outcrop at Lost Creek is exclusively that of the Battle Spring Formation. Due to the soft nature of the formation, the Battle Spring Formation occurs largely as sub-crop beneath the soil. The alluvial fan origin of the formation yields a complex stratigraphic regime which has been subdivided throughout Lost Creek into several thick horizons dominated by sands, with intervening named mudstones. Lost Creek is currently licensed and permitted to produce from the HJ horizon; we are currently seeking amendment of the licenses to be able to produce from the typically lower KM horizon.

The Company occasionally performs leach testing on various samples from the Lost Creek Project. Most recently, in 2010 we performed leach testing on samples from the KM Horizon of the Lost Creek Project (currently in the permit-licensing stage). Seven samples obtained from one-foot sections of core were tested for mineral recovery using the same test methods as in prior tests from the HJ Horizon (currently licensed for production at Lost Creek, and being recovered in Mine Unit 1). Twenty-five pore volumes of various bicarbonate leach solutions were passed through the samples. Uranium recovery ranged from 54.1 to 93.0% with an average uranium recovery of 80.6%. These results are similar to earlier leaching and recovery tests conducted on behalf of the Company on samples from the HJ Horizon, which returned results consistently averaging 82 – 83%. We believe these results are consistent with industry experience.

Pathfinder Mines Corporation: Shirley Basin Mine Site (Shirley Basin, Wyoming) and Lucky Mc Mine Site (Gas Hills Mine District, Wyoming)

As a part of the Pathfinder acquisition, we now own the Shirley Basin and Lucky Mc mine sites in the Shirley Basin and Gas Hills mining districts of Wyoming, respectively, from which Pathfinder and its predecessors historically produced more than seventy-one million pounds of uranium, primarily from the 1960s through the 1990s. Pathfinder’s predecessors included COGEMA, Lucky Mc Uranium Corporation, and Utah Construction/Utah International.

Both Lucky Mc and Shirley Basin conventional mine operations were suspended in the 1990s due to low uranium pricing, and facility reclamation was substantially completed. We assumed the remaining reclamation responsibilities including financial surety for reclamation, at Shirley Basin and at the Lucky Mc mine site. The Lucky Mc tailings site was fully reclaimed and, at the time of our acquisition, was in the process of being transferred to the U.S. Department of Energy. Therefore, we assumed no obligations with respect to the Lucky Mc tailings site, which were retained by the seller upon closing, or the NRC license at the site. We do not have plans for the further exploration or development of the Lucky Mc property during 2016.

Together with property holdings of patented lands, unpatented mining claims, and State of Wyoming and private leases totalling more than 5,500 acres (nearly 3,700 acres at Shirley Basin (approximately 1,500 hectares); approximately 1,800 at Lucky Mc (approximately 750 hectares)), we also acquired all historic geologic, engineering and operational data related to the two mine areas. Our project at Shirley Basin (the “Shirley Basin Project”) is located in Carbon County, Wyoming, approximately 40 miles south of Casper, Wyoming. The project is accessed by travelling west from Casper, on Highway 220. After travelling 18 miles, turn south on Highway 487 and travel an additional 35 miles; the entrance to Shirley Basin Mine is to the east.

In addition to the two projects and related data, we acquired an extensive U.S. exploration and development database estimated to comprise hundreds of project descriptions in more than twenty states, including thousands of drill logs and geologic reports. Our geology team continues with its evaluation of this database, assessing opportunities for monetizing this additional asset.

Under the terms of our acquisition of Pathfinder, we are obligated to pay a 5% production royalty on production at the Shirley Basin Project under certain market conditions. That royalty will be limited by the following market conditions: (i) if the reported spot price exceeds $55 for at least a consecutive four week period at any time prior to June 30, 2016 the 5% gross royalty is capped at $6,625,000; (ii) if the reported spot price exceeds $45, but does not exceed $55 for at least a consecutive four week period at any time prior to June 30, 2016 the royalty cap is reduced to $3,700,000; (iii) if the reported spot price does not exceed $45 prior to June 30, 2016 the royalty is terminated. To this time, the royalty has not been triggered. The amount of production royalty, if triggered, may be purchased back at any time at our election.

The tailings facility at the Shirley Basin site is one of the few remaining facilities in the United States that is licensed by the NRC to receive and dispose of byproduct waste material from other in situ uranium mines. We assumed the operation of the byproduct disposal site and accepted deliveries throughout 2015 under several existing contracts.

Preliminary Economic Assessment for Shirley Basin Uranium Project

In 2014, we issued a Technical Report on Resources for the Shirley Basin Uranium Project Carbon County Wyoming (August 27, 2014). Subsequently, in January 2015, we issued a Preliminary Economic Assessment for the Shirley Basin Uranium Project Carbon County Wyoming, January 27, 2015 (the “Shirley Basin PEA”). The current mineral resources at the Shirley Basin Project are estimated as follows:

Shirley Basin Uranium Project - Resource Summary

|

|

|

|

|

|

|

|

|

|

MEASURED

|

INDICATED

|

|

RESOURCE

|

AVG GRADE

|

SHORT TONS

|

POUNDS

|

AVG GRADE

|

SHORT TONS

|

POUNDS

|

|

AREA

|

% eU3O8

|

(X 1000)

|

(X 1000)

|

(X 1000)

|

(X 1000)

|

(X 1000)

|

|

FAB

TREND

|

0.280

|

1,172

|

6,574

|

0.119

|

456

|

1,081

|

|

AREA 5

|

0.243

|

195

|

947

|

0.115

|

93

|

214

|

|

TOTAL

|

0.275

|

1,367

|

7,521

|

0.118

|

549

|

1,295

|

|

|

|

|

MEASURED & INDICATED

|

0.230

|

1,915

|

8,816

|

Notes:

|

1.

| |

Sum of Measured and Indicated tons and pounds may not add to the reported total due to rounding. |

|

2.

| |

Mineral resources that are not mineral reserves do not have demonstrated economic viability. |

|

3.

| |

Based on grade cutoff of 0.020 percent eU3O8 and a grade x thickness cutoff of 0.25 GT. |

|

4.

| |

Measured, Indicated, and Inferred Mineral Resources as defined in Section 1.2 of NI 43-101 (the CIM Definition Standards (CIM Council, 2014)). |

|

5.

| |

Resources are reported through July 2015. |

|

6.

| |

All reported resources occur below the historical, pre-mining static water table. |

|

7.

| |

Sandstone density is 16.0 cu. ft./ton. |

Information shown in the table above differs from the disclosure requirements of the SEC. See Cautionary Note to U.S. Investors Concerning Disclosure of Mineral Resources, above.

The Shirley Basin mineral resource estimate includes drill data and analyses of approximately three thousand two hundred holes and nearly 1.2 million feet of historic drilling at the Shirley Basin Project which were acquired with the acquisition of Pathfinder. We drilled 14 confirmation holes representing approximately 6,600 feet which were included in the mineral resource estimate.

Shirley Basin History and Geology

The Shirley Basin property lies in the northern half of the historic Shirley Basin uranium mining district (the “District”), which is the second most prolific uranium mining district in Wyoming. Earliest discoveries were made in 1954 by Teton Exploration. This was followed by an extensive claim staking and drilling rush by several companies in 1957. Several important discoveries were made and the first mining was started in 1959 by Utah Construction Corp. (predecessor to Pathfinder). Underground mining methods were initially employed but encountered severe groundwater removal problems, so in 1961 Utah Construction switched to solution mining methods. This was the first commercially successful application of in situ solution mining recovery (ISR) for uranium in the United States. In 1968 market and production needs caused Utah Construction to move to open-pit mining and a conventional mill. All production within the district since that time has been by open-pit methods.

Several companies operated uranium mines within the District, however three companies were dominant. Utah Construction/Pathfinder’s efforts were focused in the northern portions of the District, while Getty was largely in the central portions, and Kerr-McGee was in the southern portions. In 1960, Getty and Kerr-McGee joined together as Petrotomics Company to build a mill for joint processing of their production. The last mining in the District ended in 1992 when Pathfinder shut down production due to market conditions. Total production from Shirley Basin was 51.3 million pounds of uranium, of which 28.3 million pounds came from the Utah Construction/Pathfinder operations which we now own.

Resources which we are currently targeting for ISR production represent unmined extensions of mineral trends addressed in past open-pit mines. These extensions had been targeted for mining but were abandoned with shut-down of the mining operations in 1992.

The Shirley Basin mining district lies in the north-central portions of the Shirley Basin geologic province, which is one of several inter-montane basins in Wyoming created 35-70 million years ago (mya) during the Laramide mountain building event. The Basin is floored by folded sedimentary formations of Cretaceous age (35-145 mya). These units were tilted by Laramide tectonic forces and subsequently exposed to erosion, creating a “paleo-topographic” surface. In the northern half of the Basin the Cretaceous units were later covered by stream sediments of the Wind River Formation of Eocene age (34-56 mya) which filled paleo-drainages cut into a

paleo-topographic surface. The source of the Wind River sediments is granitic terrain within the nearby Laramie Range to the east and the Shirley Mountains to the southwest. The Wind River Formation was subsequently covered by younger volcanic ash-choked stream sediments of the White River and Arikaree Formations of Oligocene age (23-34 mya) and Miocene age (5-23 mya), respectively.

The Wind River Formation is the host of all uranium mineralization mined within the Shirley Basin mining district. The lithology of the Wind River Formation is characterized by multiple thick, medium to coarse grained sandstones separated by thick claystone shale units. The individual sandstones and shales are typically 20 to 50 feet thick. Total thickness of the Wind River Formation ranges from approximately 400 to 500 feet. The two most dominant sandstones are named the Main and Lower Sands. The Lower Sand represents the basal sand unit of the Wind River Formation and in places lies directly above the underlying Cretaceous formations.

Uranium occurs as roll front type deposits along the edge of large regional alteration systems within sandstone units of the Wind River Formation. The source of the uranium is considered to be the volcanic ash content within the overlying White River Formation and also granitic content within the Wind River Formation itself. The Main and Lower Sands are the primary hosts to mineralization which we are currently targeting for ISR development. Studies we conducted in 2014, as well as previous studies by Pathfinder in the late 1990s, indicate that this mineralization is amenable to ISR extraction. The primary target is called the FAB Trend which represents the connecting mineral trend between two past-produced open-pits. A secondary target called Area 5 was also an ISR target for Pathfinder prior to shut-down of their mining operations in 1992.

Lost Soldier Project – Great Divide Basin, Wyoming

Acquired in 2005, the Lost Soldier project is located approximately 14 miles (22.5 kilometers) to the northeast of the Lost Creek Project. Lost Soldier has over 3,700 historic drill holes defining 14 mineralized sandstone units. We maintain 143 unpatented mining claims at Lost Soldier, totaling approximately 2,710 mineral acres. We do not currently view this property as individually material. As corporate priorities continue to be determined with respect to further exploration at the Lost Creek Property, and development at both Lost Creek and Shirley Basin, we anticipate that further technical work on Lost Soldier will continue to be completed as funding and staff time may be allocated to Lost Soldier.

The Bootheel Project, LLC and The Bootheel Project – Shirley Basin, Wyoming

Jet Metal Corp., formerly Crosshair Energy Corporation (“Jet Metal”) has been the manager of The Bootheel Project, LLC venture since 2007. Following a decision to not fund our portion of the budget for the venture’s budget year ending March 31, 2012, our ownership interest was reduced from 25% to approximately 19%. Since then, we have participated in the project’s budgets and programs, although the programs have been nominal maintenance programs. In February 2013, the private mineral lease agreements for the Bootheel property expired and were not renewed. Portions of the minerals included in the technical report issued by Jet Metal, are located on the leased lands at the Bootheel property. In June 2013, the Management Committee of the Bootheel Project chose to abandon certain unpatented mining claims at the Bootheel property, while retaining mining claims and the State of Wyoming uranium lease on which the remaining mineral resource is located. Because there is no reported mineral resource at the Buck Point property, the Management Committee determined to abandon all unpatented mining claims at Buck Point in 2013. Subsequently, the State of Wyoming mineral lease at Buck Point was relinquished. As a result, Ur-Energy’s investment in the Buck Point property was written off in 2013, at the same time that an impairment analysis of the remaining investment at the Bootheel property resulted in a $37,000 write-down because it was determined that the carrying cost was greater than the enterprise value of the underlying mineral resource. There was no activity other than land maintenance (payment of maintenance for unpatented mining claims and of state lease rentals) during 2015.

We do not anticipate further exploration or development work being conducted during 2016.

Competition and Mineral Prices