EXHIBIT 96.2

|

|

|

|

This Report titled “SHIRLEY BASIN ISR URANIUM PROJECT, CARBON COUNTY, WYOMING, USA,” dated March 4, 2024, has been prepared under the supervision of, and signed by, the following Qualified Persons:

Prepared under the Supervision of:

WWC Engineering

1849 Terra Avenue

Sheridan, WY 82801

USA

Report Prepared for:

10758 W. Centennial Road

Suite 200

Littleton, CO 80127

Cover Photo by Rob Koelling (2009)

|

|

|

|

TABLE OF CONTENTS

| 1.0 | Executive Summary | 1 |

| 2.0 | Introduction | 7 |

| 2.1 | Registrant | 7 |

| 2.2 | Terms of Reference | 7 |

| 2.3 | Information Sources and References | 7 |

| 2.4 | Inspection of the Property by Each Qualified Person | 7 |

| 2.4.1 | QP Qualifications | 7 |

| 2.5 | Previous Technical Report Summaries | 7 |

| 3.0 | Property Description and Location | 8 |

| 3.1 | Location and Size | 8 |

| 3.2 | Mineral Tenure | 8 |

| 3.3 | Title to Property | 9 |

| 3.4 | Royalties, Taxes and Fees | 11 |

| 3.5 | Significant Encumbrances or Risks to Perform Work on the Property | 11 |

| 3.5.1 | Environmental Liabilities | 11 |

| 3.5.2 | Existing and Required Permits | 11 |

| 3.5.3 | Significant Factors and Risks That May Affect Access, Title or Right to Perform Work | 13 |

| 4.0 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 14 |

| 4.1 | Physiography | 14 |

| 4.2 | Means of Access | 14 |

| 4.3 | Proximity to Population Centers | 14 |

| 4.4 | Climate and Operating Season | 15 |

| 4.5 | Property Infrastructure | 15 |

| 5.0 | History | 16 |

| 5.1 | Prior Ownership and Ownership Changes | 16 |

| 5.2 | Exploration and Development by Previous Owners and Operators | 16 |

| 5.3 | Significant Historical Mineral Resource and Mineral Reserve Estimates | 17 |

| 5.4 | Production | 18 |

| 6.0 | Geological Setting, Mineralization, and Deposit | 20 |

| 6.1 | Regional Geological Setting | 20 |

| 6.2 | Shirley Basin Stratigraphy | 20 |

| 6.3 | Project Geology | 22 |

| 6.4 | Significant Mineralization | 28 |

| 6.5 | Deposit | 30 |

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page i |

|

|

|

|

TABLE OF CONTENTS (Continued)

| 7.0 | Exploration | 34 |

| 7.1 | Drilling | 34 |

| 7.1.1 | Historic Drilling | 34 |

| 7.1.2 | Ur-Energy Confirmation Drillin | 34 |

| 7.1.3 | Geological Logging | 36 |

| 7.1.4 | Drill Holes Used in Mineral Resource Estimation | 36 |

| 7.1.5 | Material Results and Interpretation | 37 |

| 7.1.6 | QP Statements Concerning Drilling Results | 37 |

| 7.2 | Hydrogeology | 37 |

| 7.2.1 | Hydrogeology | 37 |

| 7.2.2 | Main Sand Hydraulic Properties | 38 |

| 7.2.3 | Historical Drill Holes | 39 |

| 7.2.4 | QP Comment on Results | 39 |

| 7.3 | Geotechnical Data, Testing, and Analysis | 39 |

| 8.0 | Sample Preparation, Analysis and Security | 40 |

| 8.1 | Down-hole Geophysical Logging | 40 |

| 8.2 | Coring | 41 |

| 8.3 | Drill Cuttings | 42 |

| 8.4 | Analyses and Security | 42 |

| 8.5 | Quality Control Summary | 43 |

| 8.6 | Opinion on Adequacy | 43 |

| 9.0 | Data Verification | 44 |

| 10.0 | Mineral Processing and Metallurgical Testing | 44 |

| 11.0 | Mineral Resource Estimate | 49 |

| 11.1 | Assumptions | 49 |

| 11.2 | Reasonable Prospects of Economic Extraction | 49 |

| 11.3 | Cutoff Selection | 49 |

| 11.4 | Resource Classification | 50 |

| 11.5 | Methodology | 51 |

| 11.6 | Resource Estimation Auditing | 53 |

| 11.7 | Summary of Resources | 53 |

| 11.8 | Mineral Resource Estimate Risk | 55 |

| 12.0 | Mineral Reserve Estimates | 58 |

| 13.0 | Mining Methods | 59 |

| 13.1 | Mineral Deposit Amenability | 59 |

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page ii |

|

|

|

|

TABLE OF CONTENTS (Continued)

| 13.2 | Wellfield Design | 59 |

| 13.2.1 | Revised Resources | 60 |

| 13.2.2 | Wellfield Patterns | 60 |

| 13.2.3 | Monitor Wells | 63 |

| 13.2.4 | Mining Schedule | 63 |

| 13.3 | Piping | 64 |

| 13.4 | Header Houses | 64 |

| 13.5 | Wellfield Reagents and Electricity | 64 |

| 13.6 | Mining Fleet Equipment and Machinery | 65 |

| 13.7 | Mining Fleet Personnel | 65 |

| 14.0 | Processing and Recovery Methods | 66 |

| 14.1 | Satellite Operations | 66 |

| 14.2 | Transportation | 66 |

| 14.3 | Energy, Water, Process Materials, and Personnel | 67 |

| 14.4 | Liquid Disposal | 69 |

| 14.5 | Solid Waste Disposal | 69 |

| 15.0 | Infrastructure | 70 |

| 15.1 | Roads | 70 |

| 15.2 | Electricity | 70 |

| 15.3 | Holding Ponds | 70 |

| 15.4 | Water | 70 |

| 16.0 | Market Studies | 71 |

| 17.0 | Environmental Studies, Permitting, and Plans, Negotiations, or Agreements with Local Individuals or Groups | 72 |

| 17.1 | Environmental Studies | 72 |

| 17.2 | Waste Disposal and Monitoring | 72 |

| 17.2.1 | Waste Disposal | 72 |

| 17.2.2 | Site Monitoring | 72 |

| 17.3 | Permitting | 73 |

| 17.4 | Social or Community Impact | 73 |

| 17.5 | Mine Closure Cost | 73 |

| 17.5.1 | Well Abandonment / Groundwater Restoration | 73 |

| 17.5.2 | Demolition and Removal of Infrastructure | 74 |

| 17.5.3 | Site Grading and Revegetation | 74 |

| 17.6 | Adequacy of Current Plans | 74 |

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page iii |

|

|

|

|

TABLE OF CONTENTS (Continued)

| 18.0 | Capital and Operating Costs | 75 |

| 18.1 | Capital Cost Estimation (CAPEX) | 75 |

| 18.2 | Operating Cost Estimation (OPEX) | 76 |

| 18.2.1 | Wellfield Development Costs | 76 |

| 18.3 | Accuracy of the CAPEX and OPEX Estimates | 76 |

| 18.4 | Risk | 77 |

| 19.0 | Economic Analysis | 79 |

| 19.1 | Assumptions | 79 |

| 19.2 | Cash Flow Forecast and Production Schedule | 79 |

| 19.3 | Taxation | 80 |

| 20.0 | Adjacent Properties | 81 |

| 21.0 | Other Relevant Data and Information | 82 |

| 22.0 | Interpretation and Conclusions | 83 |

| 22.1 | Conclusions | 83 |

| 22.2 | Sensitivity Analysis | 83 |

| 22.3 | Risk Assessment | 84 |

| 22.3.1 | Resource and Recovery | 84 |

| 22.3.2 | Markets and Contracts | 85 |

| 22.3.3 | Operations | 86 |

| 22.3.4 | Social and/or Political | 86 |

| 23.0 | Recommendations | 87 |

| 24.0 | References | 88 |

| 25.0 | Reliance On Information Provided by the Registrant | 89 |

| 26.0 | Date and Signature Page | 90 |

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page iv |

|

|

|

|

TABLE OF CONTENTS (Continued)

|

| LIST OF TABLES

|

|

|

|

|

|

| Table 1. | Shirley Basin Uranium Project Resource Summary | 3 |

| Table 2. | Shirley Basin Project Mineral Title Position | 9 |

| Table 3. | 2010 Historical PMC Shirley Basin Project Resource Summary | 18 |

| Table 4. | Shirley Basin Historical Uranium Production (1960-1992) | 18 |

| Table 5. | Summary of Select Analytical Results from Shirley Basin Core | 27 |

| Table 6. | Semi-quantitative Mineral Abundance Analysis | 28 |

| Table 7. | Summary of URE Confirmation Drilling Results | 35 |

| Table 8. | Summary of Mineralized Intercepts – URE Confirmation Drilling | 35 |

| Table 9. | Leach Test Results, 1980 – Area 5 | 45 |

| Table 10. | Core Composite Sample Geochemistry | 46 |

| Table 11. | Natural Groundwater – Chemistry | 46 |

| Table 12. | Bottle Roll Leach Test Results – 2014 | 47 |

| Table 13. | Shirley Basin Project – Resource Summary by Mineral Horizon | 54 |

| Table 14. | Development Summary by Mine Unit | 63 |

| Table 15. | Summary of CAPEX Cost Estimation | 75 |

| Table 16. | Annual Operating Costs (OPEX) Summary | 77 |

| Table 17. | Cash Flow Statement | 78 |

| Table 18. | NPV Versus Discount Rate and IRR | 80 |

|

| LIST OF FIGURES

|

|

|

|

|

|

| Figure 1. | Location Map | 2 |

| Figure 2. | Photo from FAB Trend Looking Northeast Over Reclaimed PMC Pit 3 | 8 |

| Figure 3. | Property, Access and Infrastructure Map | 10 |

| Figure 4. | Shirley Basin Project Resource Areas | 17 |

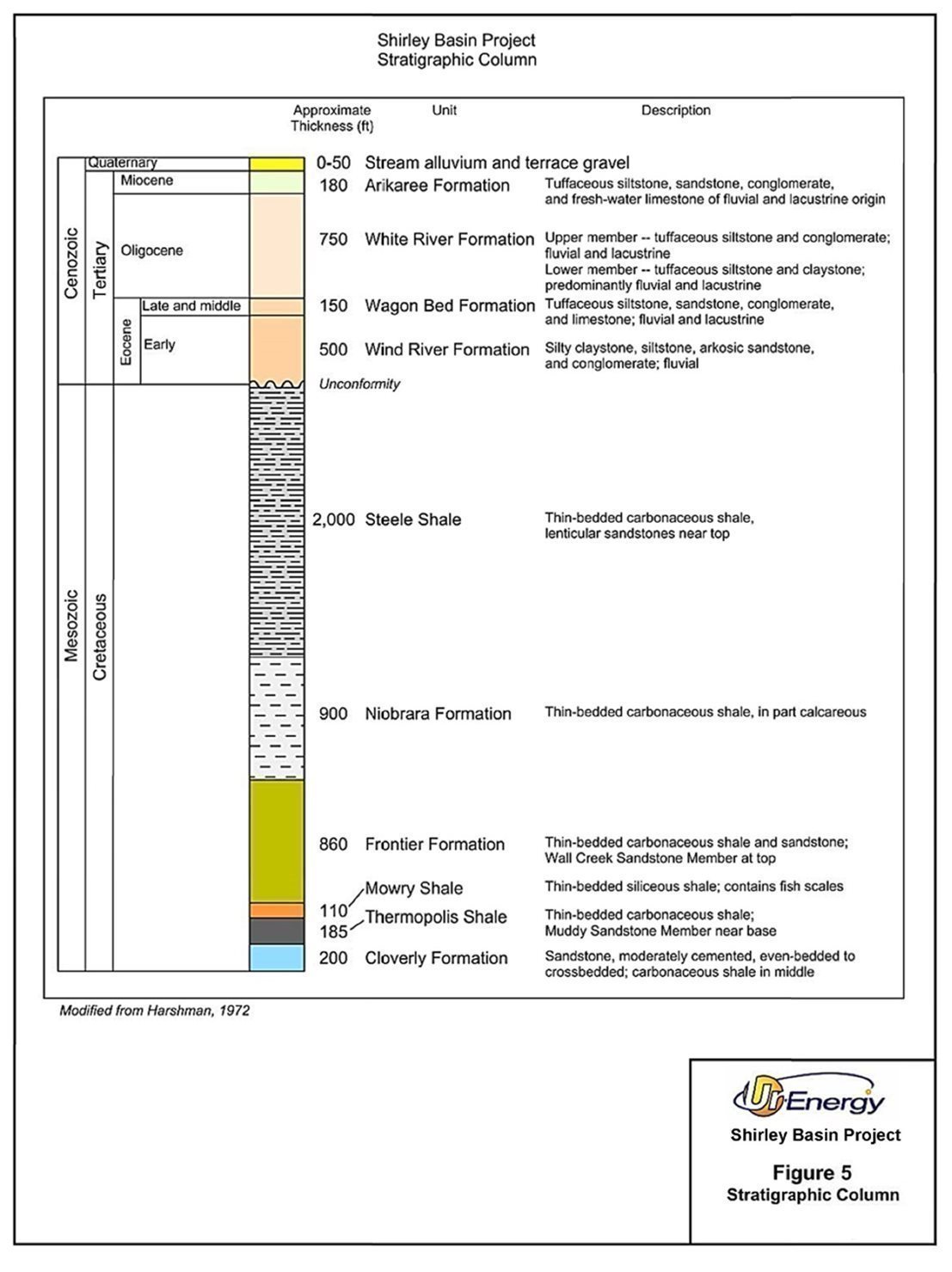

| Figure 5. | Stratigraphic Column | 21 |

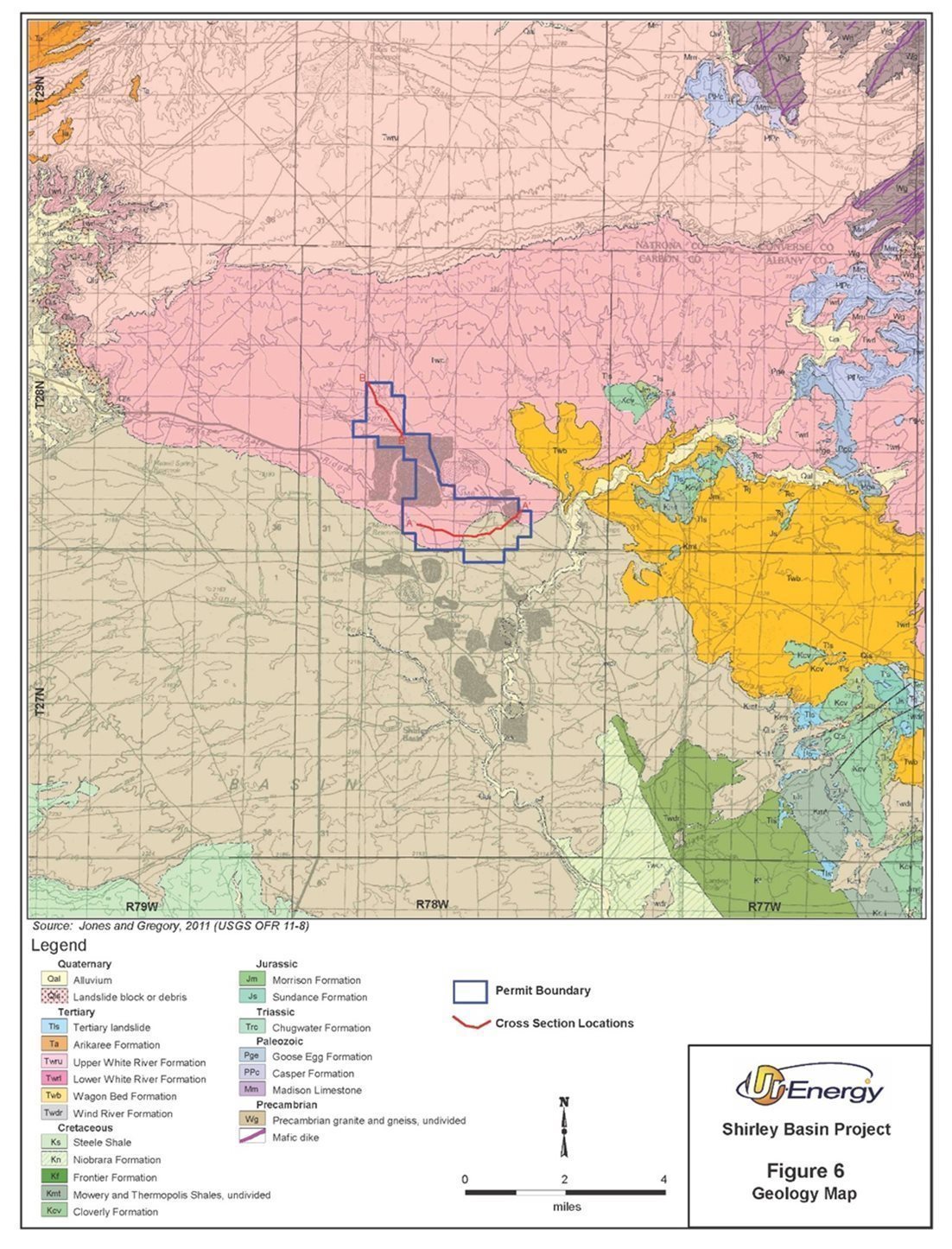

| Figure 6. | Geology Map | 23 |

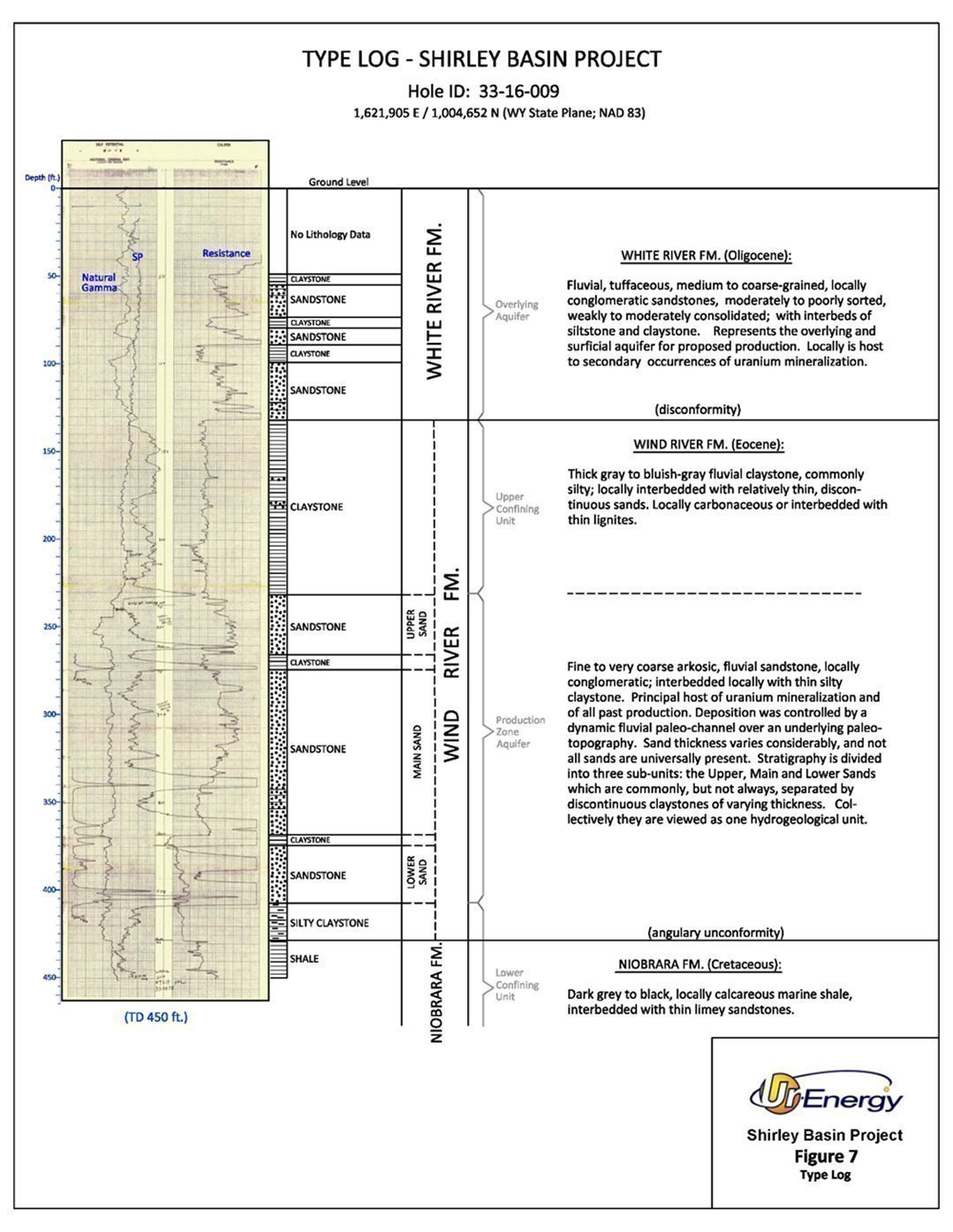

| Figure 7. | Type Log | 24 |

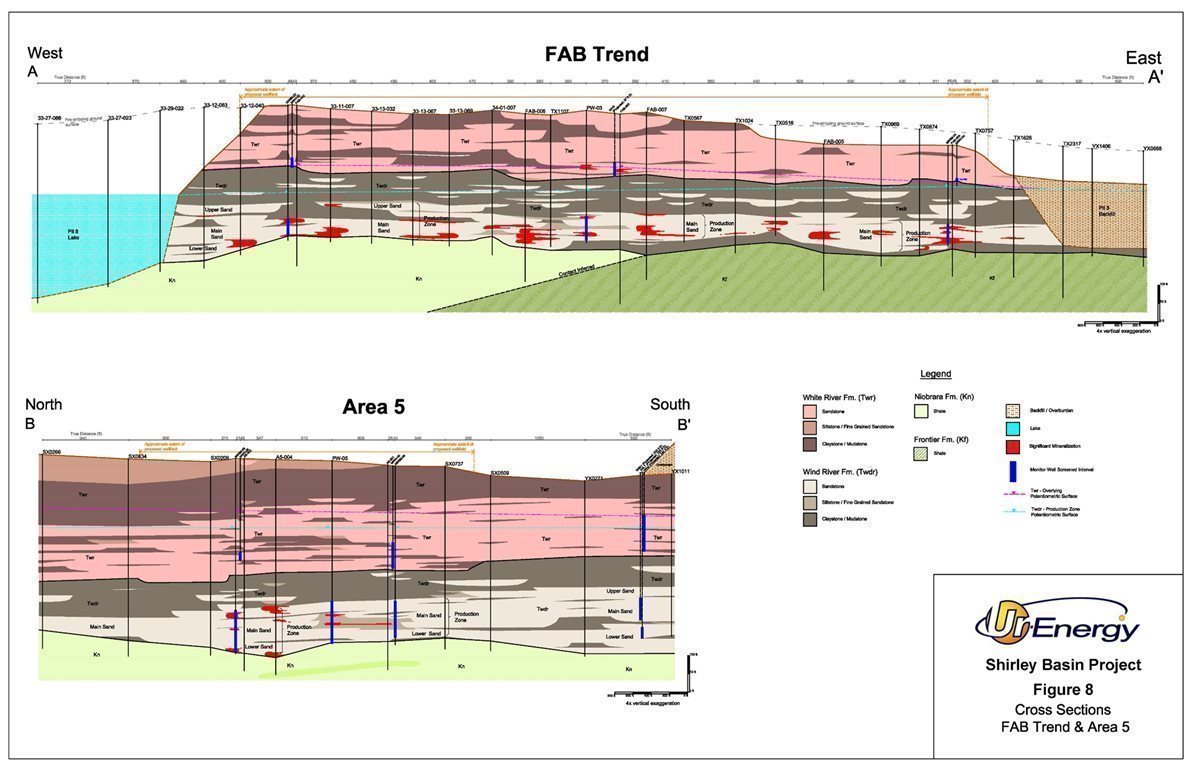

| Figure 8. | Cross Sections FAB Trend & Area 5 | 25 |

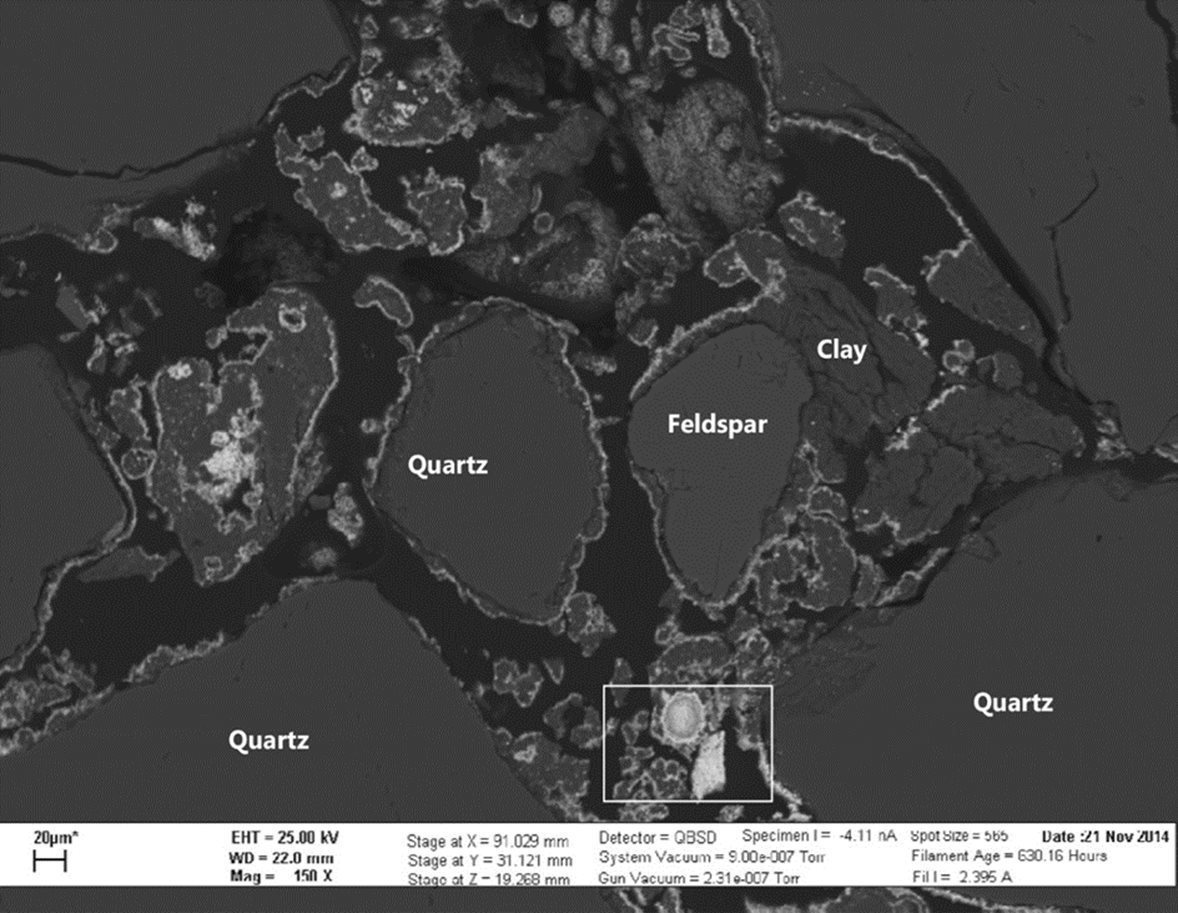

| Figure 9. | Backscatter Electron Photomicrograph – Uranium Mineralization (Bright) Associated with Clays Surrounding Quartz and Feldspar Grains | 29 |

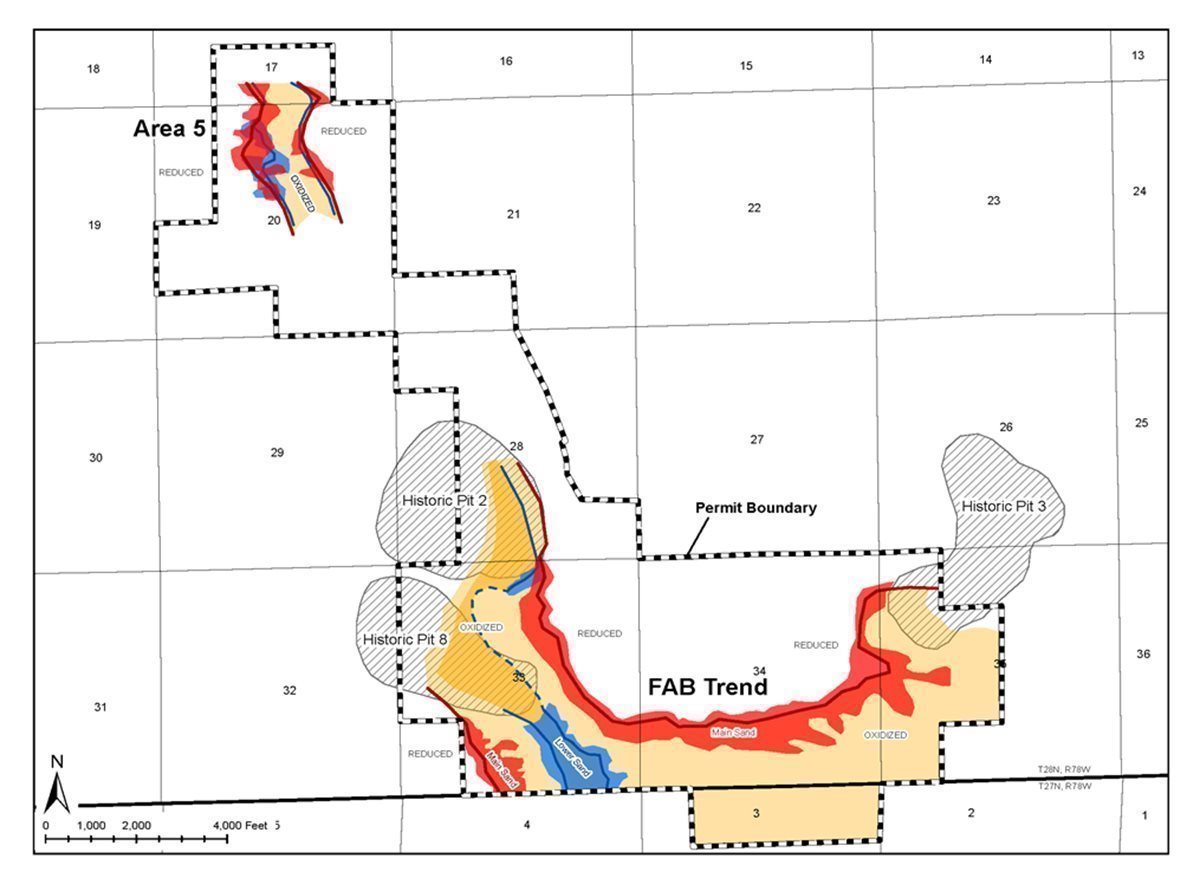

| Figure 10. | Mineralized Trends | 30 |

| Figure 11. | Photo of Shirley Basin Roll Front | 31 |

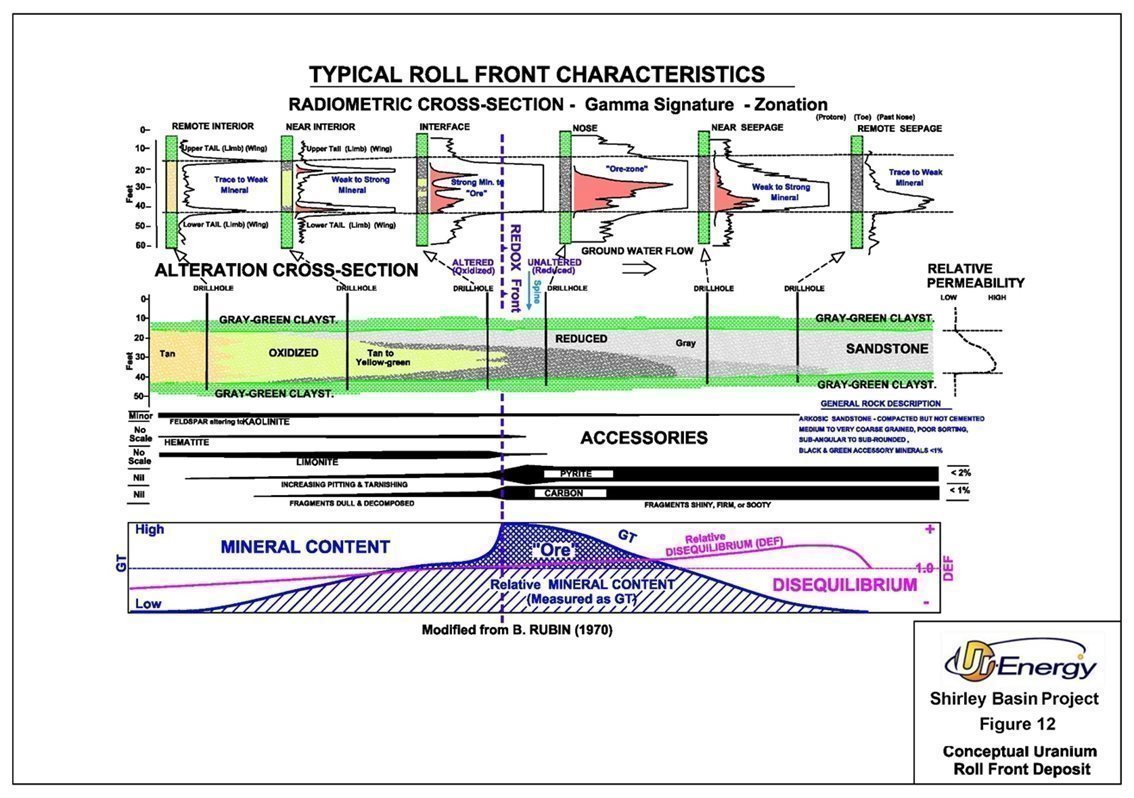

| Figure 12. | Conceptual Uranium Roll Front Deposit | 32 |

| Figure 13. | Photo of URE Confirmation Drilling | 44 |

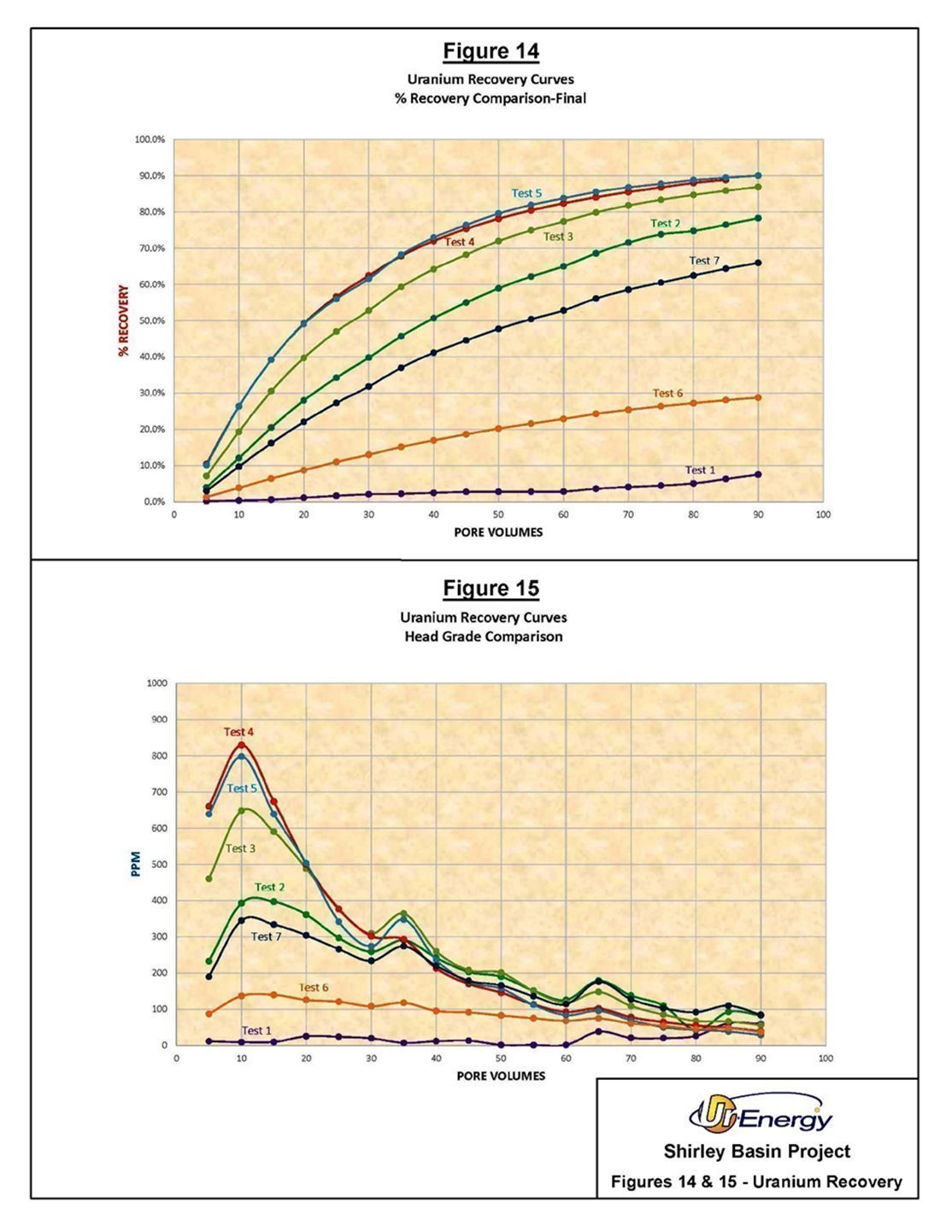

| Figure 14. | Uranium Recovery Curves % Recovery Comparison-Final | 48 |

| Figure 15. | Uranium Recovery Curves Head Grade Comparison | 48 |

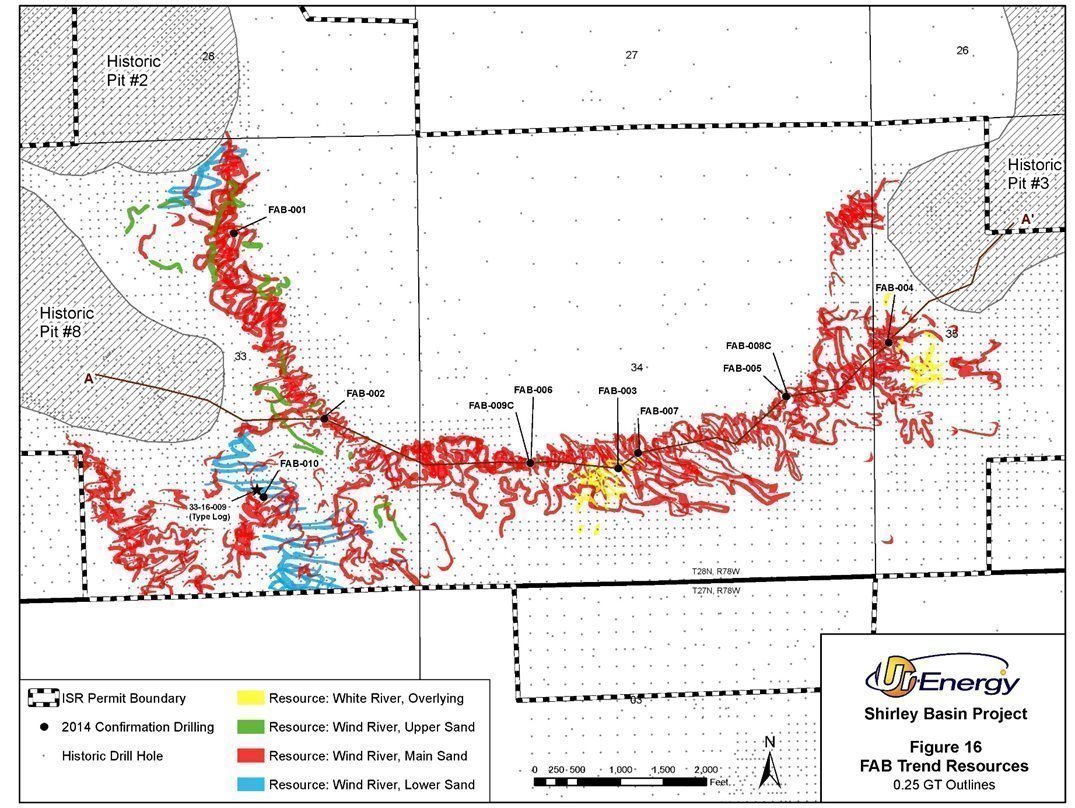

| Figure 16. | FAB Trend Resources | 56 |

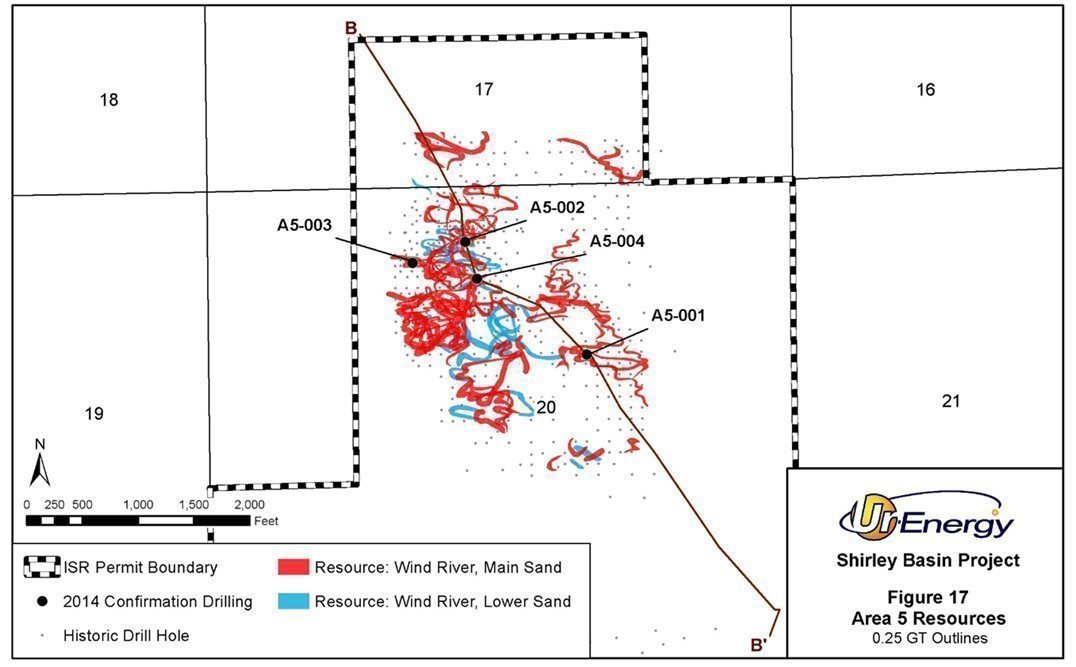

| Figure 17. | Area 5 Resources | 57 |

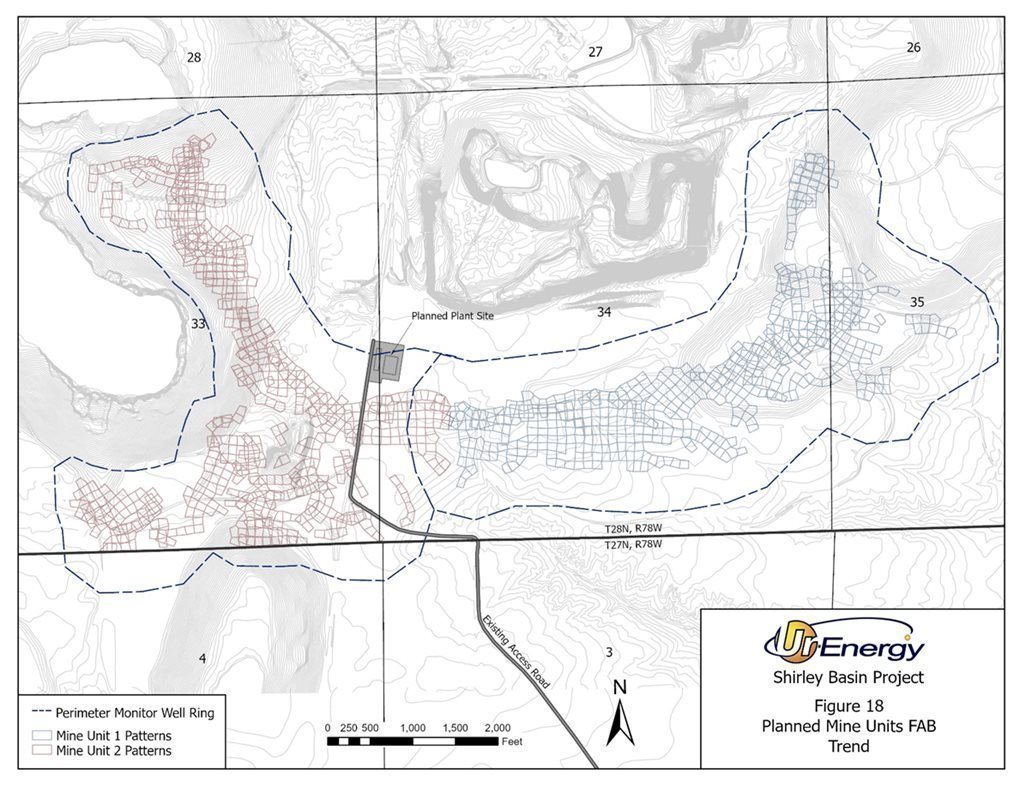

| Figure 18. | Planned Mine Units FAB Trend | 61 |

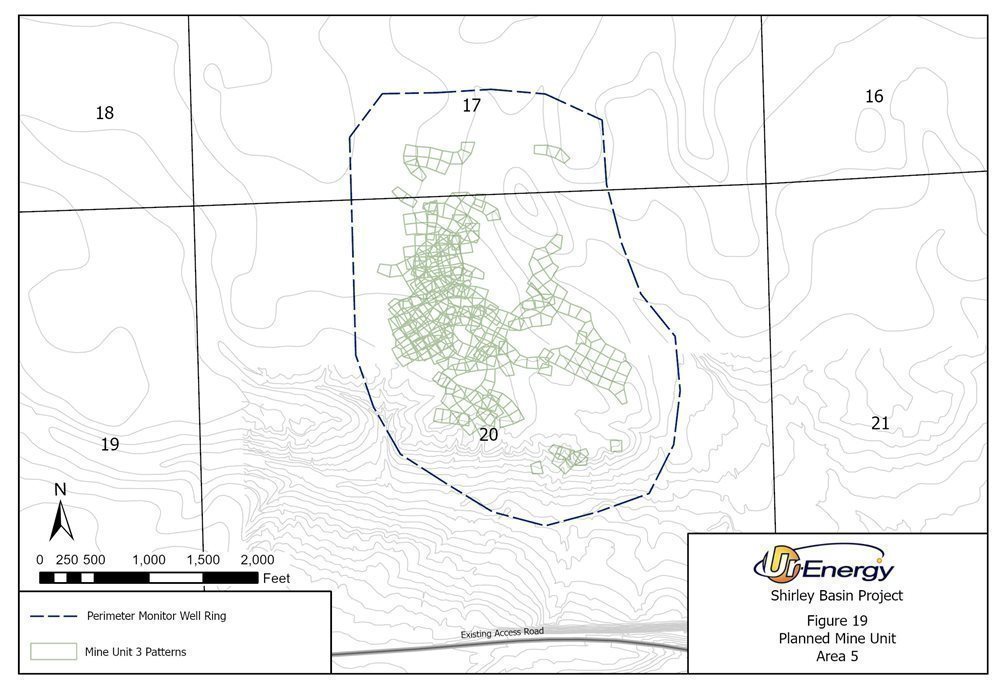

| Figure 19. | Planned Mine Unit Area 5 | 62 |

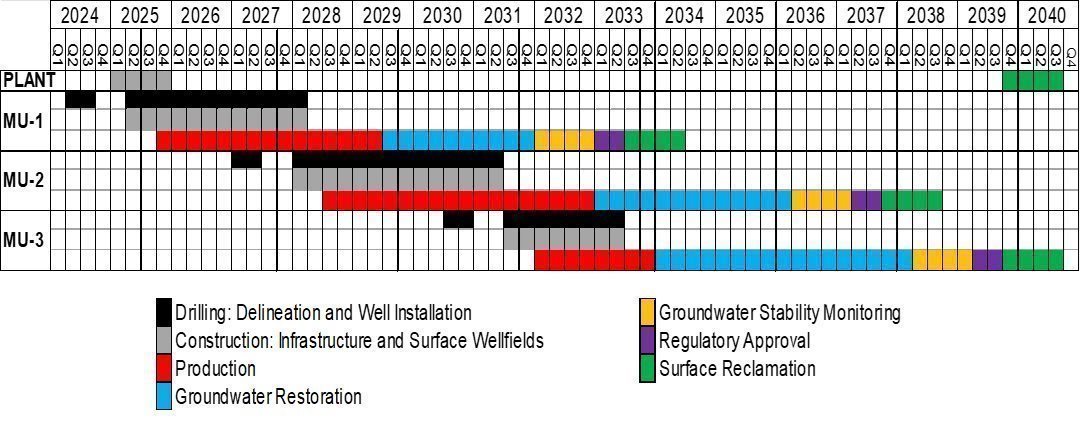

| Figure 20. | Life of Mine Schedule | 64 |

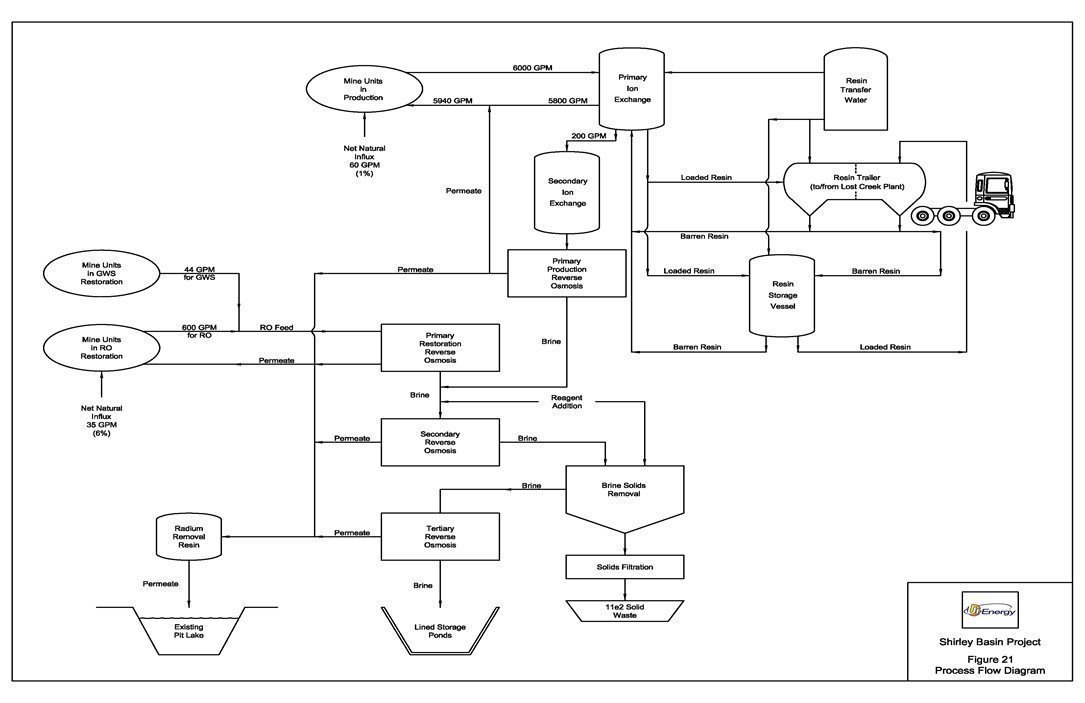

| Figure 21. | Process Flow Diagram | 68 |

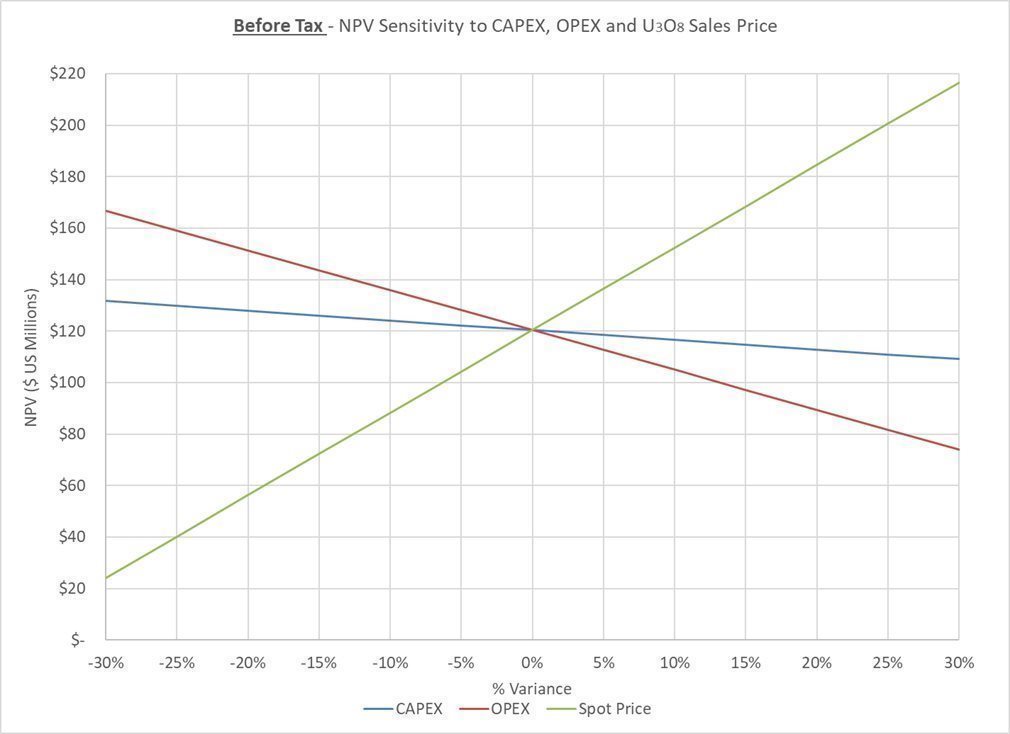

| Figure 22. | Before Tax NPV Sensitivity to Price, OPEX and CAPEX | 83 |

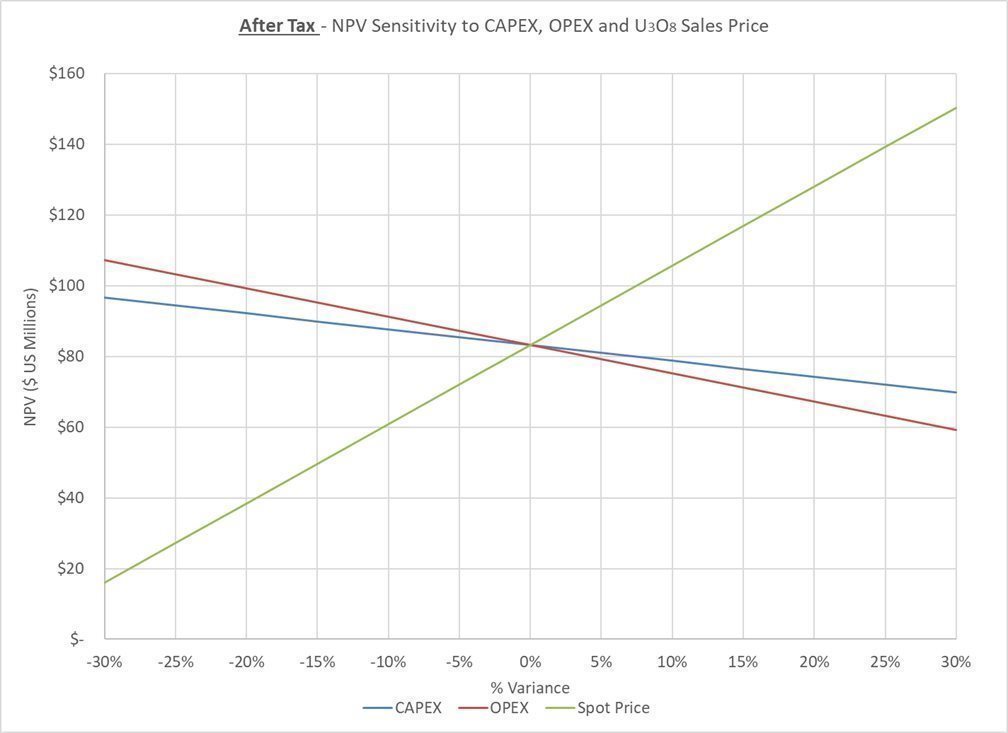

| Figure 23. | After Tax NPV Sensitivity to Price, OPEX and CAPEX | 84 |

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page v |

|

|

|

|

LIST OF ABBREVIATIONS

| AEA | Atomic Energy Act |

| AEC | U.S. Atomic Energy Commission |

| ALARA | As Low As Reasonably Achievable |

| API | American Petroleum Institute |

| BGS | Below Ground Surface |

| BLM | U.S. Bureau of Land Management |

| CAPEX | Capital Expenditures |

| COC | Chain of Custody |

| COGEMA | COGEMA Mining, Inc. |

| CPS | Counts per Second |

| cu. | Cubic |

| DEF | Disequilibrium Factor |

| District | Shirley Basin Mining District |

| DOE | U.S. Department of Energy |

| e-log | Electric Log |

| EA | Environmental Assessment |

| EMP | Electron Microprobe |

| EPA | U.S. Environmental Protection Agency |

| eU3O8 | U3O8 Content from Gamma Log |

| Ft. | Feet |

| FTE | Full Time Equivalent |

| Getty | Getty Oil Company |

| gpm | Gallons per Minute |

| GT | Grade x Thickness |

| Hazen | Hazen Research, Inc. |

| HDPE | High Density Polyethylene |

| ICP-MS | Inductively Coupled Plasma Mass Spectrometry |

| IML | Inter-Mountain Labs, Inc. |

| IRR | Internal Rate of Return |

| ISL | In-situ Leach |

| ISR | In-Situ Recovery |

| IX | Ion Exchange |

| kV | Kilovolt |

| kWh | Kilowatt Hours |

| Lbs. | Pounds |

| MU | Mine Unit |

| NI | 43-101 National Instrument 43-101 |

| NPV | Net Present Value |

| NWS | National Weather Service |

| OPEX | Operating Expenditures |

| Petrotomics | Petrotomics Company |

| PFN | Prompt Fission Neutron |

| PMC | Pathfinder Mines Corporation |

| The | Project Shirley Basin ISR Uranium Project |

| PVs | Pore Volumes |

| QP | Third-Party QP Firm WWC Engineering |

| Redox | Reduction-Oxidation Interface |

| Report | Technical Report Summary |

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page vi |

|

|

|

|

LIST OF ABBREVIATIONS (Continued)

| S-K 1300 | Regulation S-K, Subpart 1300 “Modernization of Property Disclosures for Mining Registrants” |

| SEO | Wyoming State Engineer’s Office |

| SP | Spontaneous Potential |

| Teton | Teton Exploration |

| Tidewater | Tidewater Oil Company |

| Twdr | Tertiary Wind River Formation |

| Twr | Tertiary White River Formation |

| U3O8 | Uranium Oxide or Yellowcake |

| UIC | Underground Injection Control |

| UII | Utah International Inc. |

| URE | Ur-Energy Inc. |

| Utah | Utah Mining Corporation |

| Utah CM | Utah Construction and Mining Company |

| WDEQ | Wyoming Department of Environmental Quality |

| WDEQ-AQD | Wyoming Department of Environmental Quality Air Quality Division |

| WDEQ-LQD | Wyoming Department of Environmental Quality Land Quality Division |

| WDEQ-URP | Wyoming Department of Environmental Quality Uranium Recovery Program |

| WWC | Western Water Consultants, Inc. d/b/a/ WWC Engineering |

| XRD | X-ray Diffraction |

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page vii |

|

|

|

|

1.0 EXECUTIVE SUMMARY

This independent Technical Report Summary (Report) for the Shirley Basin ISR Uranium Project (the Project) has been prepared for Ur-Energy Inc. (URE) and its subsidiary, Pathfinder Mines Corporation (PMC), under the supervision of Western Water Consultants, Inc., d/b/a WWC Engineering (WWC), pursuant to Regulation S-K Subpart 1300, “Modernization of Property Disclosures for Mining Registrants” (S-K 1300). This Report identifies and summarizes the scientific and technical information and conclusions reached concerning the initial assessment to support disclosure of mineral resources on the Project. The objective of this Report is to evaluate the technical and economic viability of the Project using the most current scientific, engineering and cost information available.

This Report analyzes the planned development of a commercial uranium satellite in-situ recovery (ISR) operation at the Project, combined with existing processing operations at URE’s Lost Creek Mine in Sweetwater County, Wyoming. The evaluation uses current operational information to develop capital (CAPEX) and operating (OPEX) cost estimates for the proposed wellfields, the satellite ion exchange (IX) plant and associated infrastructure. CAPEX and OPEX estimates are provided in this Report along with an economic analysis based on these costs and projected revenue from the recovery and sale of uranium.

The Project area geology is well understood. Shirley Basin is a small structural basin formed during the Laramide Orogeny of Late Cretaceous to Early Paleogene age. During this orogeny, basement uplifting within the surrounding Granite and Shirley Mountains to the west and southwest and within the Laramie Mountains to the east and northeast formed a broad, shallow, southward-plunging basin. Within this basin, post-Laramide Paleogene sediments were unconformably deposited onto an eroded surface of mid Cretaceous strata. These Cretaceous sediments dip approximately 2-12° to the southwest. The Paleogene sediments dip approximately 1° to the north. Coarse-grained arkosic sandstones of the Eocene-age Wind River Formation are the primary host rocks for uranium deposits in Shirley Basin. The uranium mineralization occurs as roll front type deposits formed where uranium precipitated from oxidizing groundwater when it contacted reduced host rock.

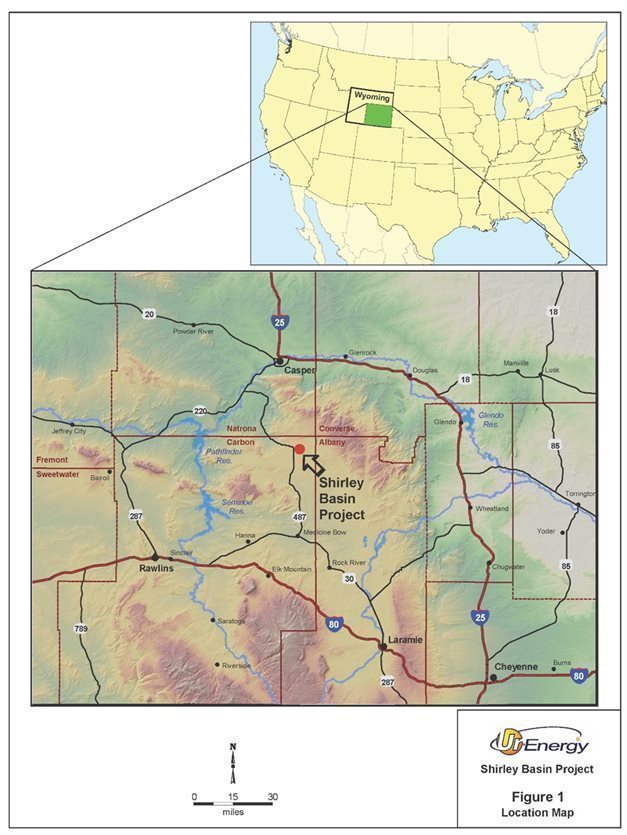

URE currently controls approximately 3,536 acres of property interests in the general area of the Project in central southeast Wyoming, approximately 40 miles south of the city of Casper (Figure 1). The fully permitted area (2,605 acres) of the Project consists of 1,770 acres of mineral lands controlled by URE. Together with the mineral rights held by URE, described in greater detail below, the Company controls 280 acres of additional surface access rights necessary to develop the Project. The Project lies within the northern portion of the historic Shirley Basin Mining District (District), the second largest uranium producing district in Wyoming with over 51 million pounds of U3O8 production from 1960 through 1992. The initial uranium discovery within this remote basin was made by Teton Exploration in 1955. URE’s Shirley Basin land holdings were largely established by Utah Mining Corporation in 1957 by staking unpatented mining claims and leasing State of Wyoming and private mineral rights. After several mergers and corporate name changes, all interests were conveyed to what is now PMC in 1976. PMC was purchased by COGEMA Mining, Inc. (COGEMA) in the 1980s. URE, through a U.S. subsidiary, acquired PMC in 2013.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 1 |

|

|

|

|

After the cessation of open pit uranium mining operations at Shirley Basin in 1992, two historical resource areas on the Project were identified as potentially suitable for ISR mining. These two areas are the FAB Resource Area or FAB Trend and the Area 5 Resource Area.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 2 |

|

|

|

|

PMC had completed over 3,200 drill holes (1.2 million ft. of drilling) in the delineation of these two resource areas, resulting in an approximate 100-ft. grid of drill holes throughout. These resources are primarily located within the “Main” and “Lower” Sands of the Eocene-age Wind River Formation.

In 2014, URE completed a confirmation drilling campaign within the FAB and Area 5 Resource Areas. The primary goals of the program were:

|

| · | Confirmation of the location and nature of mineralization as reported by historical PMC data; |

|

|

|

|

|

| · | Stratigraphic investigation to confirm lithology and to confirm overlying and underlying hydrogeological confinement; and |

|

|

|

|

|

| · | Collection of core for leach testing and analysis of uranium, mineralogy, trace metals, disequilibrium, permeability, porosity and density. |

Based upon data from the above-described historical and confirmation drilling, a Technical Report on Resources and a Preliminary Economic Assessment were prepared (Shirley Basin Uranium Project, Carbon County, Wyoming, USA, dated August 27, 2014 and Preliminary Economic Assessment Shirley Basin ISR Project, Carbon County, Wyoming, USA, dated January 27, 2015) pursuant to Canadian National Instrument 43-101 (NI 43-101). Subsequently, a Technical Report Summary pursuant to S-K 1300, as amended, was prepared and filed in 2022.

Due to the high density drilling at the Project, all resources were classified as Measured or Indicated. There are no resources in the Inferred category. The current mineral resources at the Project are listed in Table 1.

Table 1. Shirley Basin Uranium Project Resource Summary

| RESOURCE AREA | MEASURED | INDICATED | ||||

| AVG GRADE % eU3O8 | SHORT TONS (X 1000) | POUNDS U3O8 (X 1000) | AVG GRADE % eU3O8 | SHORT TONS (X 1000) | POUNDS U3O8 (X 1000) | |

| FAB TREND | 0.280 | 1,172 | 6,574 | 0.119 | 456 | 1,081 |

| AREA 5 | 0.243 | 195 | 947 | 0.115 | 93 | 214 |

| TOTAL | 0.275 | 1,367 | 7,521 | 0.118 | 549 | 1,295 |

| MEASURED & INDICATED | 0.230 | 1,915 | 8,816 | |||

Notes:

| 1. | Sum of Measured and Indicated tons and pounds may not add to the reported total due to rounding. |

| 2. | Based on grade cutoff of 0.020 % eU3O8 and a grade x thickness (GT) cutoff of 0.25 GT. |

| 3. | Measured and Indicated mineral resources as defined in 17 CFR § 229.1300. |

| 4. | All reported resources occur below the historical, pre-mining static water table. |

| 5. | Average grades are calculated as weighted averages. |

| 6. | The point of reference for mineral resources is in-situ at the Project. |

| 7. | Mineral resources that are not mineral reserves do not have demonstrated economic viability. |

To develop the above-described uranium resources, infrastructure, including wellfields, a satellite IX plant and liquid waste disposal facilities, will need to be constructed at the Project. Three mine units (MU) are planned. Within a production wellfield, the most fundamental component of mine development and production is the production pattern. A pattern consists of one production well and injection wells which feed lixiviant to it. Injection wells are commonly shared by multiple production wells. Header houses serve multiple patterns and function as both distribution points for injection flow and collection points for production flow from the production wells. The satellite IX plant feeds injection lixiviant to the header houses for distribution to the injection wells and receives and processes production flow from the header houses.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 3 |

|

|

|

|

The economic analysis presented in this Report is based on a detailed wellfield design prepared as the company advances toward wellfield construction and operations. The design primarily utilizes 5-spot pattern configurations. Pattern sizing is based on consistent injection to production well spacing of approximately 70 ft., which is the distance the lixiviant will flow between wells. Based on detailed wellfield design it is estimated that there will be a total of 1,675 patterns project wide which are divided into three mining units: MU1, MU2 and MU3. The total cumulative pattern area accounting for the stacked nature of the roll fronts for the Project is approximately 283 acres. This wellfield design requires 2,945 injection wells and 1,675 production wells for a total of 4,620 wells. In addition, 271 monitor wells are required for the planned wellfield, including 121 perimeter monitor ring wells and 150 interior monitor wells. The average well depth for the Project is estimated to be 334 ft.

Using the estimated CAPEX, OPEX and closure costs presented herein, a cash flow statement is provided in Table 17. The statement assumes no escalation, no debt, no debt interest or capital repayment and no depreciation.

This Report includes tax estimates for state severance taxes, county ad valorem taxes and property taxes, all of which are directly attributable to the Project. Wyoming has no state income tax, however, before and after federal income tax estimates are included. Ur-Energy USA Inc., the parent company of PMC, files consolidated federal tax returns in the United States. Ur-Energy USA Inc. does not anticipate paying federal income taxes until the existing, and any future, tax loss carry forwards are utilized. In addition, reclamation costs can be deducted in the early years of the Project, thus also pushing out any tax liability.

The sale price for the produced uranium is assumed to vary based on a calculation of a simple average of (a) the average of the annual projections of Cantor Fitzgerald Canada Corporation, September 26, 2023; Roth MKM, October 10, 2023; PI Financial Corp. October 6, 2023 and (b) UxC, LLC Q4 2023 Market Outlook (Mid Price Scenario Projection from 2023 to 2040) (UxC, LLC Q4 2023) (See Chapters 16 and 24). UxC is a leading independent nuclear industry market research and analysis company that publishes comprehensive market outlook reports for uranium which include future price projections. The revenue for the cash flow estimate was developed using the GT contour mineral resource estimate for the Project, and further assumes that, based on an 80% recovery factor of those pounds potentially under pattern, approximately 6.0 million pounds of U3O8 will be recovered from the Project’s currently identified Mineral Resources.

The CAPEX cost estimates presented herein are based on personnel and capital equipment requirements, as well as wellfield layouts, process flow diagrams, tank and process equipment and buildings at URE’s Lost Creek Mine which were used to estimate costs at the Project. The Project has pre-mining development and capital costs of $40.7 million including: total plant capital of $24.4 million, initial wellfield installation cost of $13.1 million, labor costs of $2.9 million, and operating costs of $0.3 million. Remaining CAPEX costs are for sustaining capital requirements at the mine site and are primarily associated with water treatment additions as needed and replacement equipment used in future operations of the plant and the wellfields. The sustaining capital cost is estimated to be $9.2 million. The sustaining capital estimate is based on the actual previous purchases of the same equipment and/or vendor prices. There is no contingency included in the capital estimates as they are based on purchases at URE’s Lost Creek Mine and current budgets for water treatment equipment.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 4 |

|

|

|

|

OPEX estimates were developed by evaluating each process unit operation and the associated required operating services (power, water, air, waste disposal), infrastructure (offices, shops and roads), salary plus benefit burden, and environmental control (heat, air conditioning, monitoring). The OPEX estimate is based on URE’s permitting and development plan, deliverables, process flow sheets, process design, materials balance and project manpower schedule. The annual OPEX and closure cost summary is provided in Table 16.

The Net Present Value (NPV) calculations assume that cash flows occur in the middle of the accounting periods. The NPV is calculated from the discounted cash flow model and is based on the CAPEX, OPEX and closure cost estimates, a variable future uranium price and the anticipated construction and production schedule. The Project is estimated to generate net cash flow over its life of $175.3 million before income tax and $119.0 million after income tax. Payback is estimated during the third quarter of 2027. The Project has a calculated before tax Internal Rate of Return (IRR) of 83.7 percent and a before tax NPV of $120.4 million applying an eight percent discount rate. When income taxes are included in the calculation, the after-tax IRR is 69.0 percent and the after tax NPV is $83.2 million applying an eight percent discount rate. The estimated cost of uranium produced is $54.89 per pound including severance taxes plus all operating and capital costs, with an estimated operating cost of $24.40 per pound.

URE utilized costing data for both CAPEX and OPEX available from the Lost Creek Mine, the costing numbers used in this analysis are therefore believed to be reliable. However, since the final detailed designs for the Project are not yet complete, and initial purchases and contracts have not been made for the project, the predicted level of accuracy of this Report is estimated at +/- 10 percent subject to the assumptions herein.

Cautionary Statement:

This Technical Report Summary is preliminary in nature and includes mineral resources. Mineral resources that are not mineral reserves do not have demonstrated economic viability. There is increased risk and uncertainty to commencing and conducting production without established mineral reserves that may result in economic and technical failure which may adversely impact future profitability. The estimated mineral recovery used in this Technical Report Summary is based on site-specific laboratory recovery data as well as URE personnel and industry experience at similar facilities. There can be no assurance that recovery of mineral resources at this level will be achieved. There is no certainty that the preliminary economic assessment will be realized.

WWC has assumed that URE’s operations at the Project will be conducted in conformance with applicable laws, regulations, and requirements of the various federal and state agencies. It is also assumed that organization and management controls have been and will continue to be established to ensure compliance with applicable regulations and implement URE’s policies for providing a safe working environment including the philosophy of maintaining radiation exposures as low as reasonably achievable (ALARA).

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 5 |

|

|

|

|

WWC has weighed the potential benefits and risks presented in this Report and have found the Project to be potentially viable and meriting further evaluation and development. There is no certainty that the mineral recovery or the economic analysis presented in this Report will be realized. In order to advance the Project to the full potential benefits described in this Report, positive results are required on the following recommended activities as discussed in Chapter 23.0.

|

| · | URE should continue with its work on advancing the project toward construction of facilities and installation of wellfields. The pre-mining development and capital costs to construct facilities and install wellfields, included in Table 15, are estimated to be $40.7 million. These activities and related costs are assumed to occur in 2024, 2025 and 2026 for the purposes of the economic analysis included here. The costs for construction design and management are included in this amount. |

|

|

|

|

|

| · | URE should complete its pre-construction design, engineering work, and installation of the first monitoring ring followed soon after by construction of the satellite facility and the first wellfield. Satellite construction should include wastewater management processes and procedures with the goal of concentrating and minimizing RO brine production and maximizing permeate output. |

|

|

|

|

|

| · | URE has a history of innovative research and development (R&D) projects that lower costs, improve operations, and minimize impacts of ISR operations. URE should continue evaluating opportunities to decrease costs and increase efficiencies, including related to its new injection well installation technology. |

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 6 |

|

|

|

|

2.0 INTRODUCTION

2.1 Registrant

This independent Report was prepared for URE by WWC. The Project is in Carbon County, Wyoming, USA. URE is incorporated in Canada with principal executive offices located at 10758 West Centennial Road, Suite 200, Littleton, Colorado 80127. The Report has been prepared for URE in accordance with the guidelines set forth under Regulation S-K, Subpart 1300 “Modernization of Property Disclosures for Mining Registrants” (S-K 1300). The purpose of this Report is to report mineral resources and assess the potential economic viability of ISR operations at the Project.

2.2 Terms of Reference

PMC is a wholly owned subsidiary of URE. The Project is operated by PMC and this Report has been prepared for URE to report mineral resources and assess the potential economic viability of ISR operations at the Project.

2.3 Information Sources and References

The information and data presented in this Report was gathered from various sources listed in Chapters 24 and 25. Technical information was provided to WWC by URE and includes data from other professional consultants and follows generally accepted uranium ISR practices. Mineral resource estimates are based on information presented in the Technical Report on Resources, Shirley Basin Uranium Project, Carbon County, Wyoming, USA. That NI 43-101 report is dated August 27, 2014 and was prepared by WWC.

Units of measurement unless otherwise indicated are feet (ft.), miles, acres, pounds (lbs.), and short tons (2,000 lbs.). Uranium production is expressed as pounds U3O8, the standard market unit. ISR refers to in-situ recovery, sometimes also termed in-situ leach (ISL). Unless otherwise indicated, all references to dollars ($) refer to United States currency.

2.4 Inspection of the Property by Each Qualified Person

WWC professionals have visited the site following the completion of confirmation drilling by URE in 2014. WWC professionals visited the site on January 28, 2022, and on February 1, 2022. The purpose of these visits was to observe the geography and geology of the Project site, verify work done at the site by URE, observe the potential locations of Project components, confirmation drilling and other site activities, and confirm existing site infrastructure. WWC professionals reviewed areal imagery captured on October 23, 2023 to confirm current site conditions.

2.4.1 QP Qualifications

Completion of this Report was under the direction and supervision of WWC. WWC is a third-party QP Firm (QP) as defined by Regulation S-K 1300. Additionally, WWC has approved the technical disclosure contained in this Report.

2.5 Previous Technical Report Summaries

URE filed a Technical Report Summary on the Project under S-K 1300 regulations in March 2022, as amended in September 2022. Additionally, reports conforming to NI 43-101 were also prepared and filed.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 7 |

|

|

|

|

3.0 PROPERTY DESCRIPTION AND LOCATION

3.1 Location and Size

URE controls approximately 3,536 acres of property interests in the area of the Project in central southeast Wyoming, approximately 40 miles south of the city of Casper. Within the Project, the fully permitted area (2,605 acres) consists of 1,770 acres of mineral lands controlled by URE. Together with the mineral rights held by URE, described in greater detail below, the Company controls 280 acres of additional surface access rights necessary to develop the Project. As shown in Figure 1, the Project is in an unpopulated area located in the northeastern portion of Carbon County, Wyoming USA. It is centered at approximately 42 degrees, 22 minutes north latitude and 106 degrees, 11 minutes west longitude, in Township 28 North, Range 78 West, within the 6th principal meridian.

3.2 Mineral Tenure

The Project is in the northern portion of the second largest uranium producing district in Wyoming, with over 51 million pounds of U3O8 production from 1960 through 1992. Surface mining ceased in 1992 and the mined areas underwent extensive reclamation activities (i.e., backfilling of pits, re-contouring of overburden piles, re-vegetation, etc.). Figure 2 illustrates the results of this reclamation. Most of the old mine areas are now rolling grasslands, with five pit lakes occupying the lowlands.

Figure 2. Photo from FAB Trend Looking Northeast Over Reclaimed PMC Pit 3

The permitted Project area includes 1,770 acres of mineral rights to locatable minerals held by the Company. This total consists of 1,330 acres of U.S. lode mining patents (nine patents), 370 acres of federal unpatented lode mining claims (29 claims), and 70 acres (two tracts) of fee minerals. Table 2 summarizes the relevant mineral title position of URE within the permitted Project area.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 8 |

|

|

|

|

The surface of all unpatented lode mining claims is controlled by the U.S. Bureau of Land Management (BLM), with URE possessing the right to use as much of the surface as is necessary for exploration and mining of the claims, subject to compliance with all federal, state and local laws and regulations. Surface use on BLM-administered federal lands is governed by federal regulations.

Table 2. Shirley Basin Project Mineral Title Position

| Property | US Patent Number, Claim Name or Legal Location | Acres |

| 9 Lode Mining Patents | 1198523, 1207111, 1207112, 1231199, 49-69-0017, 49-69-0020, 49-69-0025, 49-73-0072, and 49-73-0073 | 1,330 acres |

| 29 Unpatented Lode Mining Claims | DOE 1, DOE 2, DOE 14, DOE 15, DOE 16, DOE 17, DOE 26, DOE 27 and DOE 28; LMB 8, LMB 10, LMB 12, LMB 160 and LMB 162; COKE 1, COKE 3, COKE 4 and COKE 5; A5-1, A5‑2, A5-3, A5-4 and A5-5; FGAP 1, FGAP 2 and FGAP 3; LMB 234, LMB 235 and LMB 236 | 370 acres |

| Fee Minerals (2 tracts) | Portions of Sections 20, Township 28 North, Range 78 West, 6th Principal Meridian (e.g., SENE, Section 20; N1/2NWSE and NWNESE Section 20) | 70 acres |

| Total Mineral Acres: 1,770 acres | ||

3.3 Title to Property

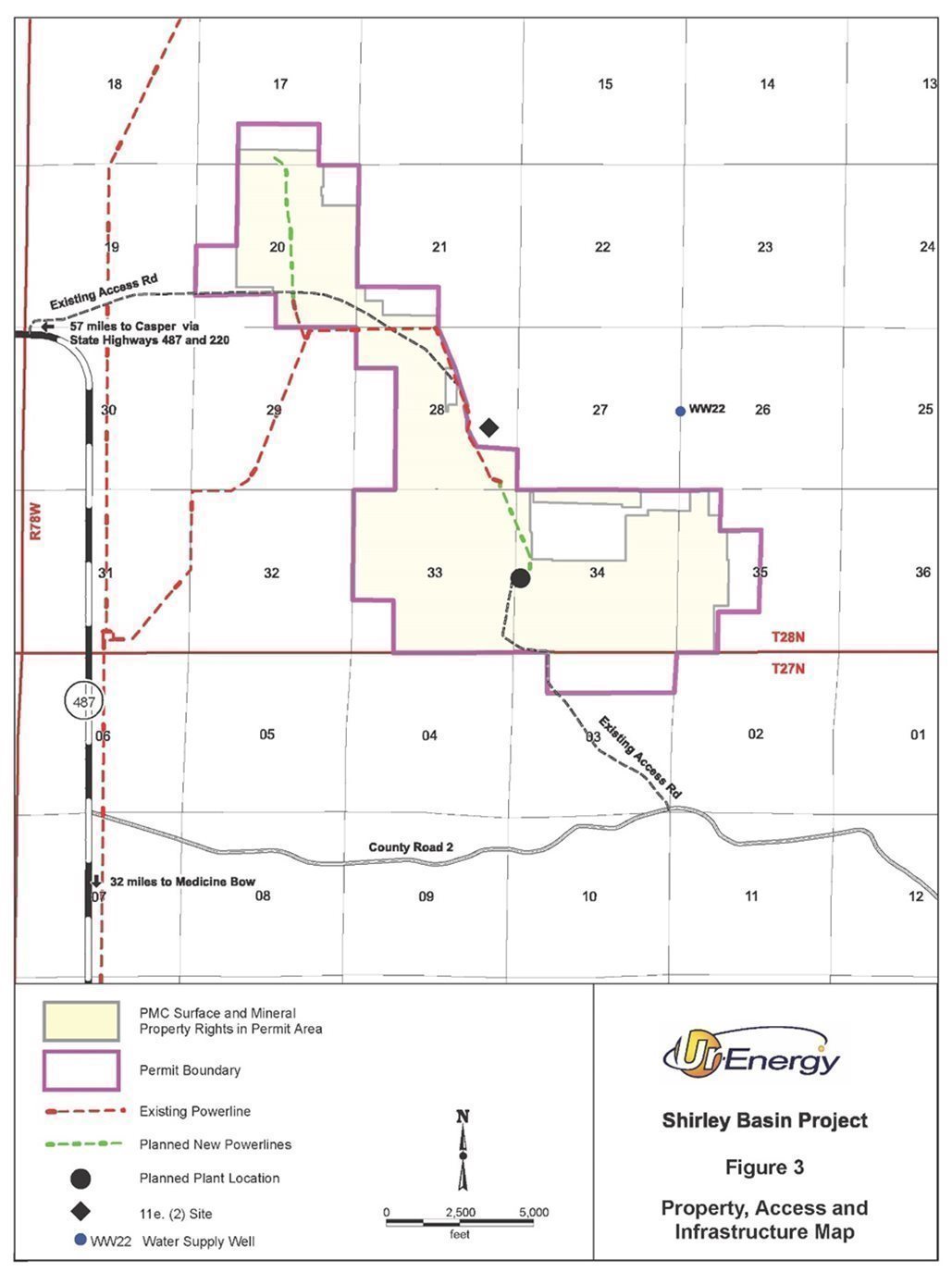

URE, through its wholly owned subsidiary PMC, owns the patented lands at the Project and controls the federal unpatented lode mining claims, and other real property interests which make up the balance of the Project (Figure 3), and through which legal access to the Project is provided. The mineral interests for the lands on which reported resources are located are 100% owned or controlled by URE, subject to the royalty interests described below.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 9 |

|

|

|

|

Title to the unpatented mining claims is subject to rights of pedis possessio against all third-party claimants as long as the claims are maintained. The unpatented mining claims do not have an expiration date. Affidavits have been timely filed with the BLM and recorded with the Carbon County Clerk’s Office attesting to the payment of annual maintenance fees to the BLM as those fees are established by law from time to time. In addition to routine periodic land status reviews by company personnel, formal mineral title reports are prepared from time-to-time for URE by mineral title attorneys.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 10 |

|

|

|

|

3.4 Royalties, Taxes and Fees

There are no production royalties at the FAB Resource Area where the majority of the defined resources are located.

Within Area 5, approximately 202 acres are subject to a formulaic royalty interest which totals approximately 0.5%. On two other tracts at Area 5 (30 acres in the southern portion and 40 acres in the southeastern portion), uranium and associated minerals are subject to different formulaic royalties which are approximately 1%. Currently, there is no known mineral resource on these 70 acres. A 0.5% royalty was included for the resources in Area 5. Additionally, certain use fees are in place on some lands in Area 5, based upon an annual disturbance-level calculation.

URE is also required to pay various state and local taxes related to production and the assessed value of the property. These taxes are in the form of severance, ad valorem gross products, and personal and real property taxes. The economic analyses presented herein also provide the results of the analyses for before income tax and after income tax, which includes U.S. federal and Illinois state income taxes. There is no State of Wyoming income tax, and all sales are assumed to take place in Illinois where the conversion facility is located. There is no state income tax in Wyoming. Maintenance fees will be paid to the BLM on an annual basis, pursuant to the existing regulations, for the unpatented mining claims held at the Project.

3.5 Significant Encumbrances or Risks to Perform Work on the Property

3.5.1 Environmental Liabilities

The environmental liability for the Project falls under the jurisdiction of the State of Wyoming, Department of Environmental Quality (WDEQ) Land Quality Division (LQD).

The current cost estimate to reclaim the work that has been completed at the Shirley Basin ISR Mine to date is $91,900.

URE maintains separate reclamation bonds to reclaim disturbance resulting from historical conventional mining and the adjacent licensed tailings facility. The tailings facility is operated independently from the Project. Likewise, the reclamation of the historical mining is not dependent on the Project. These reclamation bonds are separate from the Project and are not included in the economic analysis in this Report.

3.5.2 Existing and Required Permits

In May 2021, the URP granted a Source and Byproduct Materials License (WYSUA-2010) and the LQD issued a Permit to Mine (PT0846) to recover uranium at the Project. These two authorizations, together with the U.S. Environmental Protection Agency (EPA) aquifer exemption for the Class III Underground Injection Control (UIC) area, were the final major authorizations required at Shirley Basin to be approved to construct and commence production operations at the Project. In April 2020, the BLM issued its final decision regarding an Environmental Assessment (EA) on the Project and approving the Plan of Operations for the Project. Accordingly, all major permits and authorizations required to operate the Project, are in place and include the following:

|

| · | BLM issued a Record of Decision on April 27, 2020. |

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 11 |

|

|

|

|

|

| · | WDEQ has issued several permits including: | |

|

|

|

|

|

|

|

| · | Permit PT0846, which includes an aquifer exemption, was granted on May 4, 2021. (EPA aquifer exemption received April 2021.) |

|

|

|

|

|

|

|

| · | URP issued a Source and Byproduct Material License WYSUA-2020 on May 4, 2021 which authorizes up to 6,500 gallons per minute from wellfield production and up to 2,000,000 pounds of dried U3O8 product though no CPP is proposed for the Project at this time. |

|

|

|

|

|

|

|

| · | Air Quality Permit P0027097 was issued on November 24, 2020. |

|

|

|

|

|

|

|

| · | WYPDES Permit WY0096466 was granted on December 31, 2019. |

Additional minor permits/authorizations that will be required before operations begin include the following. Each of these is routine, and may commonly be obtained in days or weeks:

|

| · | Approval by WDEQ-LQD of the Hydrologic Test Report assessing: aquifer conditions, monitor well locations and depths, pattern areas and depths, soil survey results, road and topsoil locations, baseline water quality data and potential between adjacent mine units; |

|

|

|

|

|

| · | Construction Storm Water NPDES Permits (WDEQ Title 35-11) are obtained under a general permit based on projected construction activities; |

|

|

|

|

|

| · | Industrial Stormwater NPDES Permit (WDEQ Title 35-11) - An Industrial Stormwater NPDES will be required for the plant area; |

|

|

|

|

|

| · | A Class V UIC permit (WDEQ Title 35-11) will be applied for following installation of an approved site septic system during facility construction; and |

|

|

|

|

|

| · | Wyoming State Engineer’s Office (SEO) groundwater appropriations will be applied for prior to the installation of water supply wells at the Project. |

The Project lies within Carbon County, Wyoming. Carbon County regulates certain land use and aspects of proposed operations including the septic system and building. Carbon County issued a letter on August 14, 2020, stating the in situ project is in accordance with the current zoning resolution. Therefore, no zoning amendment will need to be pursued.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 12 |

|

|

|

|

3.5.3 Significant Factors and Risks That May Affect Access, Title or Right to Perform Work

There are ongoing reclamation and surface stabilization activities associated with historical mining. Although the Project does not lie within designated sage-grouse core area, there is a sage-grouse lek within two miles of the Area 5 Resource Area which will continue to be monitored.

Wind turbines, if built on top of a mineralized area, have the potential to limit the mineral owner’s ability to access a mineral resource. While there is ongoing wind energy development in Wyoming, there is likely only a slight risk of wind development in Shirley Basin moving north towards the Project. The nearest wind turbine is approximately seven miles to the south of the Project (U.S. Geological Survey 2024). The annual average wind speed at 80 meters at the Project would be suitable for commercial wind development (U.S. Department of Energy 2022). However, given the historical mining areas and the general topography of the area, it seems unlikely commercial wind development would seek to encroach on the Project area. This risk is non-existent on property owned by PMC. While such development could pose an issue on BLM managed lands, it is noted that there is a smaller amount of the mineral acreage directly involved in recovery areas at the Project which is BLM mining claims and, therefore, again, such a risk is viewed to be extremely slight. Furthermore, the current BLM Wind Energy Program Policies and Best Management Practices (Amendment 1) specifies that “[t]o the extent possible, wind energy projects shall be developed in a manner that will not prevent other land uses, including mineral extraction, livestock grazing, recreational use, and other ROW uses.” (BLM, 2005).

No other significant factors and risks have been identified that may affect access, title, or the right or ability to perform work on the Project.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 13 |

|

|

|

|

4.0 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY

4.1 Physiography

The Project is in the northeastern portion of the Shirley Basin, which is a high, intermontane basin encompassing approximately 500 square miles in south-central Wyoming. The Basin lies within the Wyoming Basin Physiographic Province within the Rocky Mountain System and is situated between the Central and Southern Rocky Mountain Provinces (Dyman et al. 2005). It is bounded on the north and east by the Laramie Range, on the west by the Granite Mountains and on the southwest by the Shirley Mountains.

Elevations in the District range from approximately 6,900 to 7,300 ft. Topography is dominated by low rolling hills mildly dissected by minor ephemeral drainages. This is locally modified by overburden dumps and mine pits from past operations which may diverge from natural ground level by as much as 250 ft. Most pits and dumps in the District have been re-contoured and re-vegetated.

Vegetation in the Project is dominated by cool season perennial grasses and sagebrush. The grasses are a combination of native species and re-vegetated species in reclaimed areas of historical mining. The sagebrush (Artemisia tridentata) is generally short and stunted but is well adapted to the cold winter temperatures and limited precipitation that characterize the Shirley Basin. Other vegetation identified at the Project includes perennial forbs, cushion plants, semi-shrubs, cacti, shrubs, and lichens.

4.2 Means of Access

The Project area is served by Wyoming Highway 487 as depicted on Figure 1. Wyoming Highway 487 is a state maintained, two-lane, sealed asphalt road providing year around access. Access to this highway from the north (Casper) is via Wyoming Highway 220, and access from the south (Laramie or Rawlins) is via US Highway 30/287. Once on the Project, there is a crown-and-ditched gravel access road to the former mill site area. The proposed access to the ISR production areas will require upgrading approximately 1.9 miles of an existing graded access road which is reached by Carbon County Road 2 (Shirley Ridge Road). In addition to the designated routes, there are a number of tertiary or “two-track” roads that traverse the area for recreation and grazing access, as well as various other uses, including mineral exploration. The nearest airport to the Project is Casper-Natrona County International Airport located just north and west of Casper, Wyoming. Both Laramie and Rawlins also have smaller regional airports. The BNSF Railroad runs through Casper, and the Union Pacific railroad runs through Medicine Bow.

4.3 Proximity to Population Centers

The Project is in a remote area. The nearest town is Medicine Bow with a population of 245 people (U.S. Census 2024), located about 32 miles south of the Project. Casper is approximately 40 miles north of the Project. Casper, with a population of 59,038 (U.S. Census 2024), has well-established infrastructure and service industry capabilities and is a source of experienced mining personnel. The city of Laramie with a population of 31,407 (U.S. Census 2024) is located approximately 78 miles south-southeast of the Project. Rawlins, Wyoming, with a population of 8,221 (U.S. Census 2024) is located approximately 66 miles to the southwest. Federal and Wyoming highways connect all these cities and towns to the Project (see Figure 1).

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 14 |

|

|

|

|

4.4 Climate and Operating Season

The climate of the Shirley Basin ranges from arid in the central portions to semi-arid along the flanks. There is a National Weather Service (NWS) meteorological station (Shirley Basin station number 488192) approximately one mile from the Permit Area that collected data for the period of record from 1978 to 2016. The average annual precipitation measured at this station was 10.57 inches. Temperatures range from moderate in the summer to harsh in the winter. As recorded at the Shirley Basin station, average maximum temperatures in the summer (June, July and August) range from 71.8° to 80.1° Fahrenheit (F), while average minimum temperatures in the winter (December, January and February) range from 1.6° to 3.3° F. Additionally, a meteorological station was installed within the Permit Area in 2014 which collected temperature, humidity, incoming solar radiation, wind speed, and wind direction. The data collected by this station are generally within range of the long term averages at the NWS station. Due to the high elevation of Shirley Basin, summers are short, but the weather is favorable for working throughout the year. However, there can be periods of time when exploration and drilling activities on the Project will be affected by winter weather, spring storms or adverse ground conditions.

4.5 Property Infrastructure

Site infrastructure is excellent. A well-graded road traverses the Project and provides access from the south and will be upgraded. The former mill facility has been dismantled and disposed of; however, several support facilities remain, including a modular field office building and a large, heated wash and lubrication bay which is currently used for storage and equipment maintenance. A regional power transmission line (69 kV) passes through the northern portions of the Project. Also, an existing energized power line leads to a substation near the field office, and from there a currently inactive powerline (power poles only) extends to the FAB Trend. A licensed active waste disposal site for 11e.(2) byproduct material is currently operating adjacent to the fully reclaimed tailings complex. Heavy equipment on site for that operation includes a D-9 bulldozer and a medium sized backhoe.

Water supply needs are currently limited to drilling water, supplied by well WW22 which is capable of producing over 25 gallons per minute (gpm). Several backup water wells are also present but have not been utilized to date. The existing water wells currently installed at the Project are capable of providing sufficient supply for domestic and other potential operational requirements. Additional new and appropriately sited water source wells will be considered for future site use. Also, water impounded in the reclaimed mine pits is suitable for use in drilling and other non-potable uses would be available pending construction of approach ramps.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 15 |

|

|

|

|

5.0 HISTORY

The District is the second largest uranium producing district in Wyoming. It has a rich mining history that includes the first commercial uranium ISR operation in the United States and the earliest development of roll front geologic concepts. Over 51 million pounds of uranium were produced from this District from 1960-1992, including over 28 million pounds produced from the lands currently controlled by URE.

The initial uranium exploration and early discoveries within this remote basin were made by Teton Exploration (Teton) in 1954 - 1955. However, this remained largely unknown to the public until 1957 when a land rush swept the region. Utah Mining Corporation (Utah) acquired a large land position in search of additional resources to feed its Lucky Mc mill in the Gas Hills Uranium District. Utah’s position focused on the northern portions of the District.

Other significant early operators in the District were Tidewater Oil Company (Tidewater) later, Getty Oil Company (Getty), Petrotomics Company (Petrotomics) and Kerr-McGee Nuclear. These companies focused primarily on the southern portions of the District. Petrotomics started an open pit mine/mill operation in 1962 just south of the Utah property and operated through 1985. All of Kerr-McGee Nuclear’s production was processed through the Petrotomics mill. In addition, ore from the Jenkins Mine operated by the Uranium Supply Services Corporation in the southern portion of the District was processed at the Petrotomics mill.

5.1 Prior Ownership and Ownership Changes

Most of the initial land acquisition throughout what is now the Project was conducted by Utah and Tidewater (particularly Tidewater in the western FAB Resource Area) in the late 1950s. Area 5 and the eastern FAB Resource Area were initially acquired by Utah from third parties who had located unpatented lode claims. By 1963, Utah had acquired title and interest to the unpatented lode claims from various third parties, and after doing so, merged with Utah Construction and Mining Company (Utah CM). In 1968, Utah CM patented the lode claims, which make up the majority of the Area 5 and eastern FAB Resource Areas. In 1973, Utah CM conveyed its interests to Utah International Inc. (UII). In 1976, UII conveyed its interest to Lucky Mc Uranium Corporation, which subsequently changed its name to Pathfinder Mines Corporation (PMC). PMC was purchased by COGEMA in the 1980s, and, in 2013, URE acquired PMC.

With respect to portions of the FAB Resource Area, Tidewater initially located unpatented lode claims, then sought and received patents (early 1960s). Tidewater then merged with Getty, who received additional patents for lode and mill site claims (1973), which completes the interests in the western FAB Resource Area. In 1984, Getty conveyed its interest to Getty Mining Company, which subsequently conveyed the interest to Petrotomics. In 1985, Petrotomics deeded all its interest in what is now the FAB Resource Area to PMC. Additionally, PMC controls 29 unpatented lode mining claims within the FAB and Area Five Resource Areas. In 2005, PMC acquired a 100% interest on 70 contiguous acres from two mineral and surface fee owners southeast of, and contiguous to, the Area 5 Resource Area.

5.2 Exploration and Development by Previous Owners and Operators

Utah’s exploration operations at Shirley Basin were well managed and extremely efficient. After staking mining claims, Utah immediately commenced a successful exploratory drilling program in July 1957. Utah’s first ore-hole was drilled in August 1957 in what is now Pit 3, followed by an extensive exploration drilling program. Sufficient resources were soon discovered to warrant development, and in June 1959 underground mine construction was started in what is now the northern portions of Pit 2. Production by Utah/PMC over the years was by three different methods. Initial mining was by underground methods, with the ore shipped to Utah’s Lucky Mc mill in the Gas Hills. However, underground mine dewatering proved difficult. Consequently, underground activities were abandoned in 1963 and replaced by the first successful commercial ISR operation in the U.S., employing acid leach methods. In 1970, production demands caused Utah to switch to open pit mining. All mining past that point was by open pit mining. A mill to process the ore on site was commissioned in 1971.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 16 |

|

|

|

|

Prior to acquisition by URE more than 9,400 exploration and development rotary drilled holes were drilled and logged by Utah/PMC and Petrotomics within or near the current Project area. Most had been drilled prior to 1984 as delineation holes for past mined open pits and as regional exploration holes; however, more than 3,200 holes were drilled within the current FAB Trend and Area 5. Pre-stripping of portions of the FAB Trend had been initiated adjacent to Pit 8, and at the east end of the trend adjacent to Pit 3. Pre-stripping had progressed to approximately 50-75 ft. in depth by the time mining ceased.

5.3 Significant Historical Mineral Resource and Mineral Reserve Estimates

When PMC open pit operations in the District ceased in 1992, substantial mineral resources remained in the ground. COGEMA formed an ISL Resource Assessment Group in 1994 to evaluate remaining resources in the Project and their suitability for ISR. The primary resource area was identified as the FAB Resource Area or FAB Trend, which is primarily located in the southern portions of Sections 33, 34 & 35, Township 28 North, Range 78 West (Figure 4). This resource represents the connecting mineral trend within the Main Sand between past production in the Pit 2/8 complex and Pit 3. The Pit 2/8 complex produced approximately 18 million lbs. of U3O8 and Pit 3 produced approximately 7 million lbs. U3O8. A second area (Area 5 Resource Area), in the northwest portion of the Project (Figure 4), was also evaluated by the ISL Resource Assessment Group.

In annual uranium reserve summary reports from 1994 to 1998, COGEMA identified approximately 7 million lbs. of U3O8 in the FAB Trend and Area 5 as resources that could potentially be mined by solution methods. These earlier resource estimates are relevant as they provide an indication of the mineralization in the area; however, they do not differentiate resources in terms of currently recognized resource categories (Measured, Indicated and Inferred), and they do not meet the professional definition standards and guidelines for the reporting of exploration information, mineral resources and mineral reserves for the purpose of S-K 1300. URE has not treated this historical estimate as current mineral resources or mineral reserves, and it is superseded by the current mineral resource estimate in this Report.

In 2010, AREVA (formerly COGEMA) completed a more comprehensive resource evaluation for the FAB Trend and Area 5. Termed a “GT Layer Resource Model,” it was largely a geostatistical approach based on mineralized intercept data from historical delineation drill holes completed in the two resource areas. GT values for mineralized holes were accumulated per each 10-ft. elevation slice. The resulting GT values were contoured for each elevation slice using a kriged or distance-weighted average GT contour method, and the sub-total resources for each slice were calculated. The totals listed in Table 3 represent the total of all slices and include some mineralization in the White River Formation. No geological interpretation was involved.

Figure 4. Shirley Basin Project Resource Areas

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 17 |

|

|

|

|

Table 3. 2010 Historical PMC Shirley Basin Project Resource Summary

| GT Cutoff | 0.01 | 0.10 | 0.25 | 0.50 | 1.00 | |

| FAB Area | lbs U3O8 Avg GT Avg Grade | 15.81M 0.025 0.030% | 12.43M 0.359 0.138% | 9.28M 0.631 0.218% | 6.25M 1.035 0.322% | 3.43M 1.784 0.493% |

| Area 5 | lbs U3O8 Avg GT Avg Grade | 2.58 M 0.022 0.016% | 1.47M 0.239 0.106% | 0.80M 0.450 0.188% | 0.35M 0.772 0.275% | 0.10M 1.334 0.461% |

| Total Resource | lbs. U3O8 | 18.39M | 13.90M | 10.08M | 6.60M | 3.53M |

Note: These resources were not modeled using GT contouring methods. URE believes that the kriging methods used to develop these resources were not appropriate and may have inflated the resources. This data is provided for informational purposes only and URE does not treat these estimates as mineral resources or mineral reserves.

The estimation was done using multiple GT cutoffs for both the FAB and Area 5 Resource Areas.

This historical resource estimate is relevant as it provides an indication of the magnitude of remaining resources in the FAB and Area 5 Resource Areas. However, not all the resources in this historical estimate should be considered as suitable for ISR production. Also, this historical resource estimate does not differentiate resources in terms of currently recognized resource categories (Measured, Indicated and Inferred), and does not meet the professional definition standards and guidelines for the reporting of exploration information, mineral resources and mineral reserves for the purpose of S-K 1300. URE has not treated this historical estimate (Table 3) as current mineral resources or mineral reserves, and it is superseded by the current mineral resource estimate in this Report.

5.4 Production

No production has taken place within the District since 1992. Prior to that time, based on internal PMC reports, a combined 51,263,100 lbs. U3O8 were mined from the District. Of this total, PMC (and its predecessor company - Utah) produced 28,263,100 lbs. U3O8. PMC’s total production was the result of a combination of underground mining, ISR operations and open pit mining within property currently controlled by URE. Historical production within the District is shown in Table 4.

Table 4. Shirley Basin Historical Uranium Production (1960-1992)

| Company | Method | Pounds U3O8 |

| Utah | Underground | 1,200,000 |

| Utah | ISR | 1,500,000 |

| Utah/PMC | Open Pit | 25,563,100 |

| Petrotomics | Open Pit | 22,000,000 |

| Homestake/Others | Open Pit | 1,000,000 |

|

| Total | 51,263,100 |

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 18 |

|

|

|

|

Underground Mining – Utah began underground mine construction in June 1959. Underground methods were selected because portions of the reserves were too deep for open pit mining under the small production quotas allocated at the time by the U.S. Atomic Energy Commission (AEC). The first ore was produced in March 1960. The ore was transported to Utah’s Lucky Mc mill in the Gas Hills Uranium District for processing. Unstable mining conditions, attributed to the unconsolidated nature of the ore sands and high flow of groundwater, resulted in high mining costs. Near the end of this mining phase, 4,000-5,000 gpm had to be pumped from the mine to maintain the operation. Underground drifting stopped in November 1963 when the decision was made to switch to solution mining. A total of 110,000 tons of ore were mined from underground operations containing 1.2 million lbs. U3O8.

ISR Operations – It was recognized early in the underground mining phase that the troublesome issues related to poorly consolidated permeable host sands and high groundwater flow could be positive factors for ISR. For this reason, research into ISR began in 1961. This research focused on the site hydrological conditions, optimum geometry of wellfield patterns and production/injection well designs.

Commercial ISR operations commenced in 1963 and continued into 1970, when dewatering associated with open pit mining stopped operations. These were the first commercial ISR operations in the U.S. and were considered technologically and economically successful. Produced mining solutions were pumped to a uranium recovery plant on the property, containing ion exchange, elution and stripping columns. A uranium slurry from this plant was concentrated and shipped to the Lucky Mc mill for final processing. A total of 1.5 million lbs. U3O8 were produced through ISR methods.

Open Pit Mining – In November 1968, Utah announced plans to initiate large-scale open pit mining operations and to construct an 1,800 ton/day mill on its Shirley Basin property. Overburden stripping began in 1969 and, in July 1970, ISR production was halted. The mill first began processing ore from open pit operations in 1971. Production came from three large open pits: Pits 2, 3 and 8. Pit 3 and most of Pit 2 were on ground initially acquired by Utah. Pit 8 was on ground acquired from Petrotomics. All historical underground workings and the area mined by ISR were eventually removed by open pit mining within Pit 2. PMC’s open pit mining operations were terminated in 1992 and produced a total of 25,563,100 lbs. U3O8.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 19 |

|

|

|

|

6.0 GEOLOGICAL SETTING, MINERALIZATION, AND DEPOSIT

6.1 Regional Geological Setting

The Shirley Basin is a small structural basin with a complex structural history. The latest and most prominent structural events were associated with the Laramide Orogeny of Late Cretaceous to Early Paleogene age. During this orogeny, basement uplifting within the surrounding Granite and Shirley Mountains to the west and southwest and within the Laramie Mountains to the east and northeast formed a broad, shallow, southward-plunging basin. Within this basin, post-Laramide Tertiary sediments were unconformably deposited on an eroded surface of mid Cretaceous strata. These Cretaceous sediments dip approximately 2-12° to the southwest.

6.2 Shirley Basin Stratigraphy

Cenozoic and Mesozoic sediments present on the surface and in the sub-surface at Shirley Basin are illustrated stratigraphically on Figure 5. The following summarizes the geologic formations, from shallowest to deepest, below, above and including the host sandstones of the Eocene-age Wind River Formation.

Quaternary – Thin sequences of alluvial sediments occur along intermittent and perennial stream drainage systems. These fine-grained sediments have been eroded from Tertiary and Cretaceous rocks.

Arikaree Formation (Miocene), fluvial and lacustrine – This formation consists of alternating beds of fine to medium-grained, calcareous, light-gray, tuffaceous sandstones; lenticular conglomerates; and fresh-water limestones. The maximum thickness of this formation is 180 ft. While the Arikaree is not present within the District, exposures on the periphery of the structural basin have been described by Harshman, 1972.

White River Formation (Oligocene), fluvial and lacustrine – This thick sequence of tuffaceous sediments has a maximum thickness of 750 ft. An upper member consists of tuffaceous siltstones, interbedded with coarse-grained sandstone and boulder conglomerates. A lower member is predominately tuffaceous siltstones, but contains sequences of claystones, sandstones, conglomerates and fresh-water limestone. Locally, the White River Formation contains small concentrations of uranium mineralization.

Wagon Bed Formation (Eocene), fluvial and lacustrine – Where present, it consists of interbedded coarse-grained arkosic sandstones, silicified siltstones and claystones, and fresh-water limestones. The maximum observed thickness of this formation is 155 ft. It is not present in the Project area, having been removed by erosion prior to deposition of the White River Formation.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 20 |

|

|

|

|

Figure 5. Stratigraphic Column

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 21 |

|

|

|

|

Wind River Formation (Eocene), fluvial – This formation is the primary host for uranium deposits in the Shirley Basin and consists of sequences of medium to coarse-grained arkosic sandstones, interbedded with claystone shale, clayey siltstones and thin lignites. Locally, there are intervals of boulder conglomerates, although these have not been observed within the Project area. The maximum thickness of this formation ranges from 450-550 ft.

Steele Shale (Cretaceous), marine – This is the youngest Cretaceous formation recognized in the Shirley Basin. This formation consists of thin-bedded, dark gray clay shale and some siliceous, medium-grained, light-gray sandstones. The Steele Shale is soft and easily eroded. It has an estimated thickness of 1,500-2,000 ft. This formation has been removed by pre-Tertiary erosion in the Project area and is present only in the far northeastern portion of the District.

Niobrara Formation (Cretaceous), marine – This formation consists of dark gray to black locally calcareous shale, interbedded with thin limey sandstones. Total estimated thickness of this formation is 900 ft.

Frontier Formation (Cretaceous), marine – The majority of the formation consists of gray to dark gray, thin-bedded carbonaceous shale. The top of the Frontier Formation is represented by the Wall Creek Sandstone member. This member consists of a series of fine to medium-grained sandstones, interbedded with dark gray shale. The sands are cemented with calcium carbonate and are very resistive to erosion. They have also been a prolific oil producer throughout Wyoming. Thickness is approximately 110 ft. Total estimated thickness of the Frontier Formation (including the Wall Creek Sandstone) is 900 ft.

6.3 Project Geology

In the Project area, the primary hosts for uranium mineralization are arkosic sandstones of the Eocene-age Wind River Formation. This formation was unconformably deposited on gently-dipping shales and sandstones of the Cretaceous-age Niobrara and Frontier Formations. The White River Formation unconformably overlies the Wind River Formation and outcrops on the surface throughout most of the Project, with thicknesses ranging from a thin veneer in the FAB Resource Area to over 250 ft. in Area 5 (see Figure 6).

The Wind River sediments in the Project area were deposited as part of a large fluvial depositional system. The lithology of the Wind River Formation is characterized by thick, medium to coarse-grained, arkosic sandstones separated by thick claystone units. Sandstones and claystones are typically 20 - 75 ft. thick. Minor thin lignite and very carbonaceous shale beds occur locally. These fluvial sediments are located within a large northwest-trending paleochannel system with a gentle 1° dip to the north (Bailey and Gregory 2011).

The average thickness of the Wind River Formation within the Project area is approximately 230 ft. (see Figure 7). The two most dominant sandstones are named the Main and Lower Sands as shown on Figure 8 (cross section locations are shown on Figures 6, 16 & 17).

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 22 |

|

|

|

|

Figure 6. Geology Map

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 23 |

|

|

|

|

Figure 7. Type Log

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 24 |

|

|

|

|

Figure 8. Cross Sections FAB Trend & Area 5

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 25 |

|

|

|

|

The Lower Sand represents the basal sand unit of the Wind River Formation and in places lies directly above the underlying Cretaceous formations. The Main Sand typically lies approximately 15 - 25 ft. above the Lower Sand. Locally, the two sands merge where the intervening claystone unit is absent. Typical thickness of the Lower Sand ranges from 25 - 50 ft. and that of the Main Sand from 40 - 75 ft. Less dominant sands are common within the Wind River Formation. One in particular has been referred to as the Upper Sand and is present within much of the FAB Trend, lying approximately 25 ft. above the Main Sand. Claystone units are normally at least 10 ft. thick and commonly are 20 - 50 ft. thick.

The average depth to the top of the Main Sand in the FAB Trend is approximately 270 ft. and the average depth to the base of the Lower Sand is 400 ft. Area 5 is down-dip; therefore, the units are slightly deeper. The average depth to the top of the Main Sand in Area 5 is approximately 360 ft. and the average depth to the base of the Lower Sand is 490 ft.

Regional alteration systems related to roll front development followed the Wind River Formation depositional patterns. Two major alteration systems developed, one in the Lower Sand and one in the Main Sand. Major historical ore bodies in the southern portions of the District were mainly in the Lower Sand and lower alteration system, while those in the central and northern portions of the District were in both the Lower and Main Sands. PMC’s Pit 3 was mined only in the Main Sand. Pits 2 and 8 were mined in both sands and both alteration systems.

Mineralized core of the Main Sand, collected during URE’s 2014 confirmation drilling program, was described by geologists as medium- to coarse-grained, friable sandstone, clean, uncemented but weakly to moderately compacted. Laboratory testing of physical parameters of these core samples yielded an average horizontal permeability (to air) of 3,319 millidarcies, and an average porosity of 26.8%. In addition, similar testing of an overlying claystone unit yielded a vertical permeability of 4.56 millidarcies, and a sample from the underlying claystone unit had a vertical permeability of 0.93 millidarcy. The results of these initial tests indicate conditions are suitable for uranium ISR, a high permeability host aquifer confined by low permeability aquitards.

Bulk density analyses were also conducted on two core samples from the Main Sand. These analyses yielded an average tonnage factor (density) of 15.7 cubic (cu.) ft. per ton for the host sandstone. This compares favorably to the historical PMC tonnage factor of 16.0 cu. ft. per ton, which was used in URE’s current resource estimate.

Chemical analyses for trace metals and accessory minerals of 33 samples collected from the two 2014 core holes were performed by Inter-Mountain Labs, Inc. (IML) now Pace Analytical. Trace metal analysis was done using inductively coupled plasma mass spectrometry (ICP-MS) methods employing 3-acid digestion (nitric, hydrochloric and hydrogen peroxide: EPA Method 3050). All samples represent approximately one-foot intervals and were collected from within, or adjacent to, mineralized intervals. Results for selected analytes which could potentially impact uranium ISR or processing are listed Table 5 below.

| Ur-Energy – Shirley Basin ISR Uranium Project |

|

|

| Technical Report Summary – March 4, 2024 |

| Page 26 |

|

|

|

|

Table 5. Summary of Select Analytical Results from Shirley Basin Core

| Analyte | Average Concentration |

| As | 9.5 ppm |

| Mo | 10.4 ppm |

| Pb | 15.8 ppm |

| Se | 2.9 ppm |

| V | 71.0 ppm |

| C(org) | 0.17% |

| CaCO3 | 1.88% |

None of the analytes shows contents which would impede uranium recovery. Vanadium values are elevated; however, vanadium recovery during bottle roll leach tests was very low.

Petrographic and mineralogical analyses were conducted by Hazen Research, Inc. (Hazen) on behalf of PMC in 2014 on two mineralized core samples. The samples were selected from two core holes, each testing the “nose” environment of separate roll fronts in the Main Sand within the FAB Trend. Uranium analysis by Hazen showed the grade of sample FAB-8C 248.5 to be 0.26% U3O8, near the average grade for the FAB Trend. Sample FAB-9C 344.4 is of higher grade at 0.70% U3O8. Mineralogical analysis was performed on polished sections using QEMSCAN technology. Selected portions of the samples were also analyzed by x-ray diffraction (XRD).

Table 6 lists the semi-quantitative abundance analysis of the minerals identified in the two samples. The results are consistent with that of a clean uranium bearing arkosic sandstone. The main minerals are quartz, potassium-rich feldspar, and clay minerals (possibly swelling). The clay fraction varied from 9% to 14% (by mass). Clay mineralogy was not identified but is likely mostly smectite with some kaolin. Pyrite content is lower than expected, at 0.9% to 1.5%. Carbonate (calcite) content is variable. Sample FAB-8C 248.5 contained very little carbonate, while FAB-9C 344.4 was locally calcite cemented, showing a total of 6.1% carbonate. Uranium mineralization is not prevalent in calcite-rich zones. Microscopic estimation of porosity for both samples is 25%.